- Provides cracked or uncracked selenium flux

- Flux modulation and on/off control by motorized valve

- Source capacities from 300 up to 9600 cm³

- Water-cooled assembly

- Excellent flux uniformity due to beam shaping nozzle

- Avoids loss of selenium during system bakeout Datasheet

Introduction

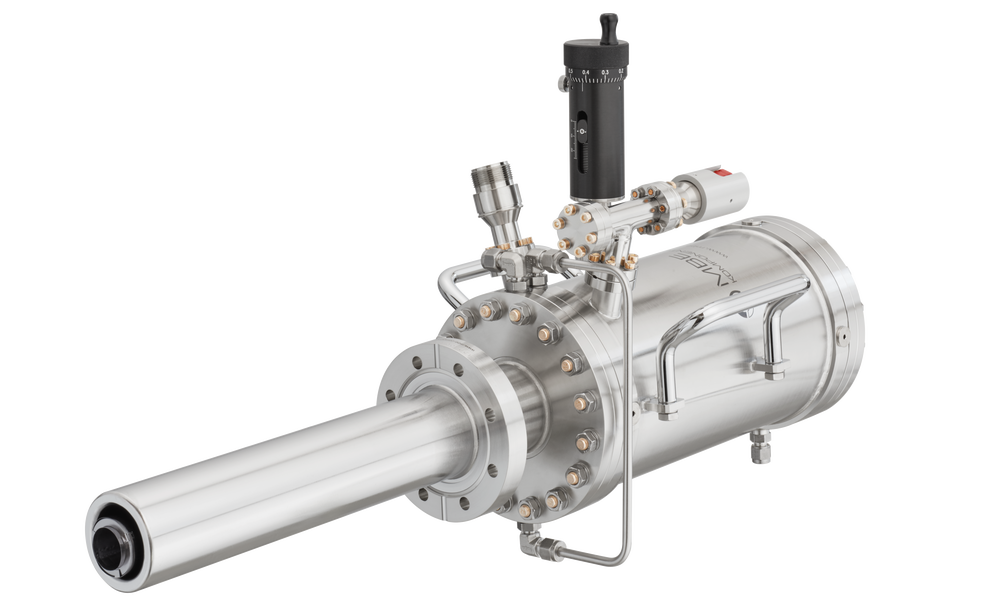

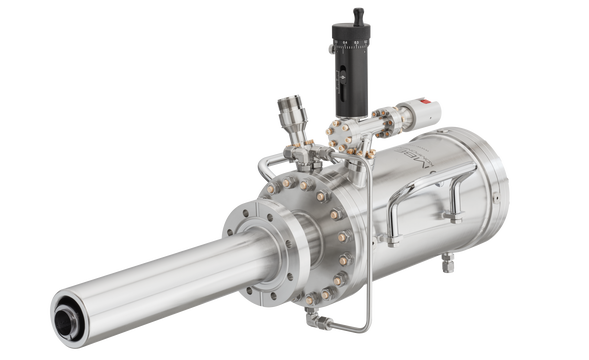

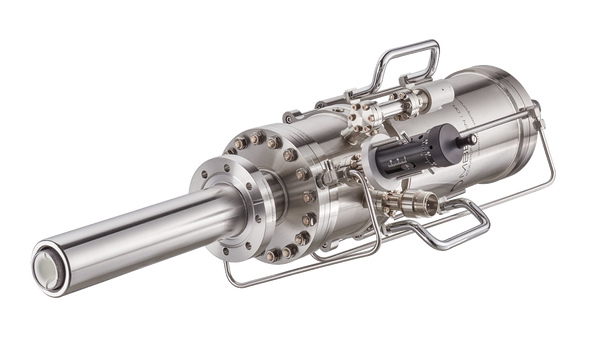

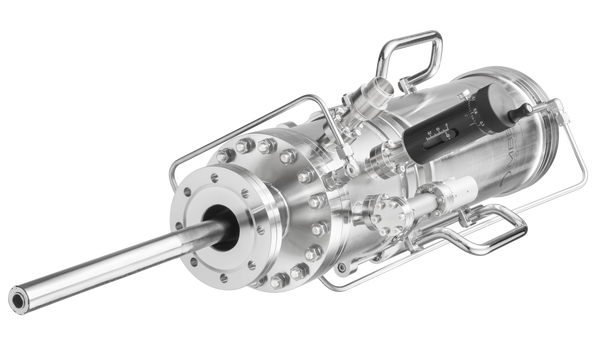

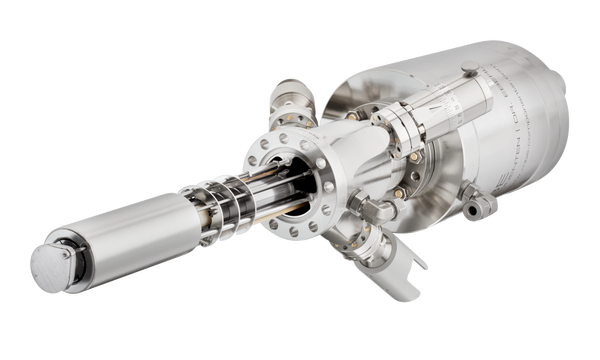

The VSCS is a valved Selenium cracker source, employed in high efficiency CIGS solar cell growth and other II-VI semiconductor material deposition processes.

Selenium beam pressure is generated in a heated large capacity crucible

with an optional inserted quartz liner. The flow rate is controlled and

switched on/off by a specially designed selenium-resistant valve whose

outlet opens into an injection tube that includes an independently

heated cracking zone. The temperature within the cracking zone can be

adjusted to generate either uncracked or cracked selenium. The use of a

beam shaping nozzle at the end of the injection tube provides excellent

flux uniformity on the substrate.

The valve design features a large cross-section orifice which allows

very good pumping properties of the reservoir. Its robust wide angle

valve design effectively eliminates the risk of locking, which is a

frequently observed problem with needle valves.

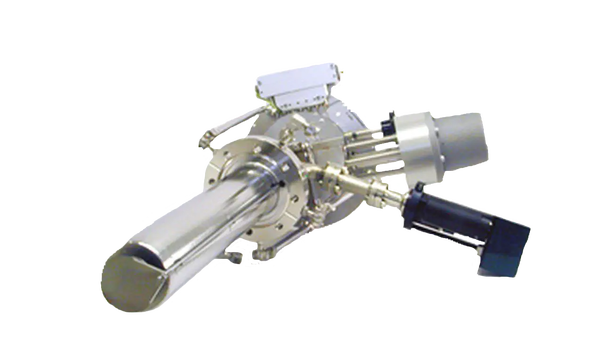

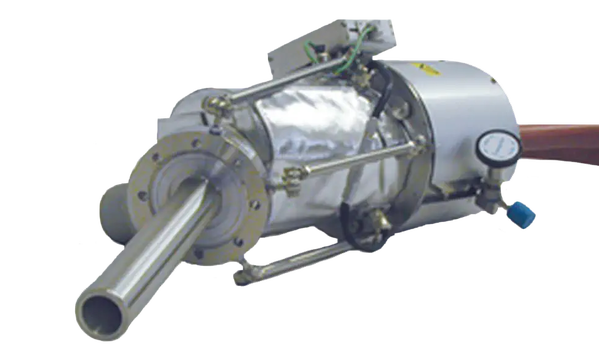

Technical details of the construction have been optimized to meet the specific requirements of research deposition applications and MBE systems. Simple system integration and excellent long-term run-to-run stability have been demonstrated. Different crucible sizes of 300 cm³ or 500 cm³ are offered on DN63CF (O.D. 4.5”).

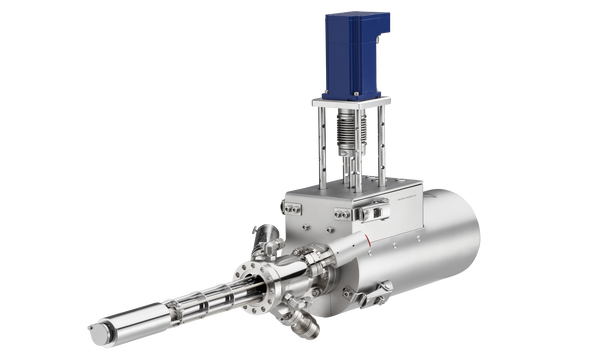

For very large capacity industrial sources please see PVSS . The figure on the right-hand side shows an industrial version, as applied in selenization processes that are part of solar cell manufacturing and other industrial thin film applications.

Application

The VSCS Valved Selenium Cracking Source has been designed for the controlled evaporation of selenium. It can be used for II-VI semiconductor thin film research and solar cell manufacturing. Other possible applications are, for example, post-growth selenization processes with or without carrier gas.

MBE-Komponenten provides support in the design of customer-specific research or production systems in order to achieve a customized source geometry, optimized for specified layer uniformity and most efficient deposition material consumption.

Co-deposition processes can be simulated on request. The simulations are based on geometric and Monte Carlo method calculations. Typical results include the lateral layer thickness distribution and material composition for multiple material co-deposition processes on semiconductor wafers as well as on large area substrates.

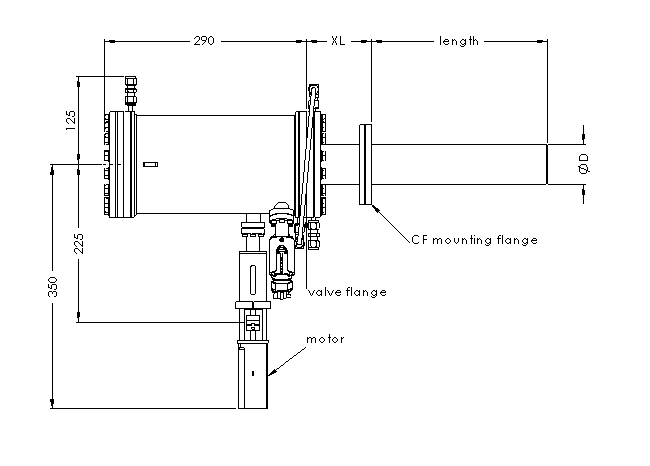

| Type | VSCS 100-300 | VSCS 100-500 |

| Crucible capacity | 300 cm³ | 500 cm³ |

| Length of injector tube | 250 to 400 mm | 250 to 400 mm |

| In-Vacuum diameter

(w/o cooling shroud) | see drawing below | contact us |

| Operating temperatures - crucible zone - cracker (no cracking) - cracker (cracking) | 250 to 370°C 350-500°C 900-1100°C | 250 to 370°C 350-500°C 900-1100°C |

| Outgassing

temperature (crucible / cracker) Max. bakeout temperature | 400° / 1200°C 250°C | 400° / 1200°C 250°C |

| Water cooling | main body injector tube (option) | main body injector tube (option) |

| Valve opening time | 1 sec | 1 sec |

| Heater circuits | - crucible + valve - cracker | - crucible + valve - cracker |

| Thermocouples | W5%Re/W26%Re (typeC) 2 thermocouples (crucible-valve / cracker) | W5%Re/W26%Re (typeC) 2 thermocouples (crucible-valve / cracker) |

| Valve control | manual or motor drive MVCU | manual or motor drive MVCU |

Dimensions