- Compatible with most MBE systems

- Large capacity 150 cm 3 evaporator

- Ideal source for Cs and Rb evaporation

- Easy and safe refilling procedure

- Precise and very fast flux control Datasheet

Introduction

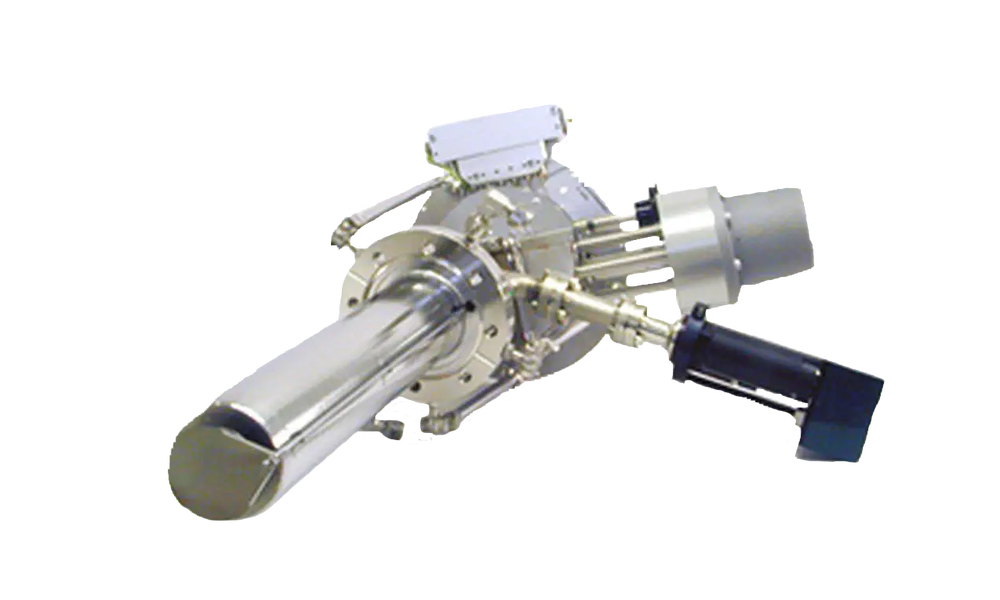

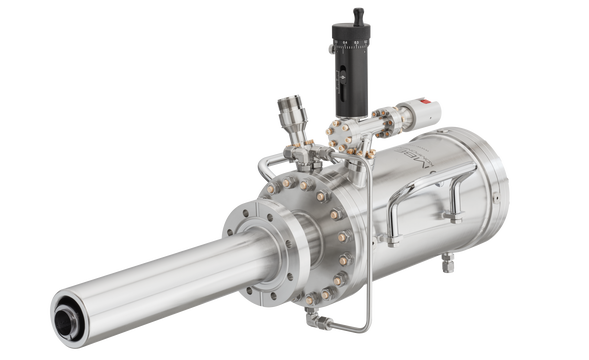

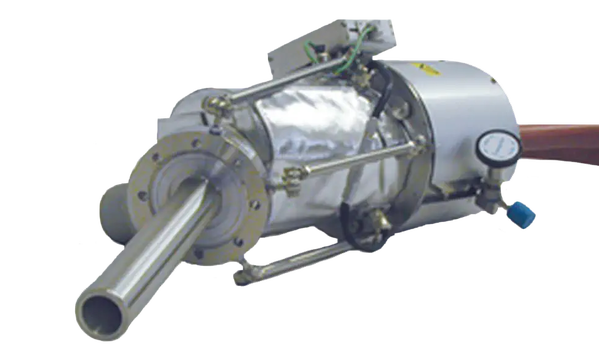

The Valved Alkali Metal Source AKS is designed for evaporation of

elemental high vapor pressure alkali metals like cesium (Cs) and

rubidium (Rb) in standard MBE or UHV systems.

The AKS provides precise metal flux stability of better ±0.1% by ±0.03K temperature control of the metal reservoir using external heating.

The integrated pneumatic all metal valve enables rapid on/off switching of the atomic beam. Its vaccum tight construction allows venting the MBE system without breaking the vaccum inside the AKS evaporator.

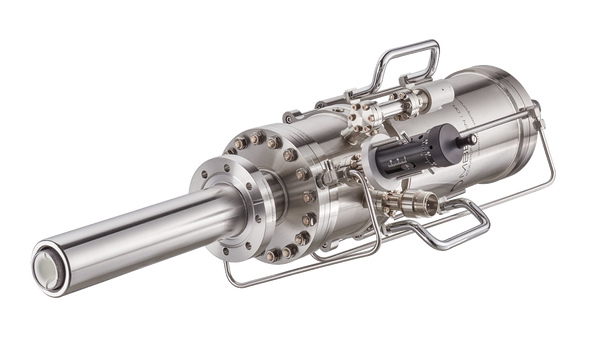

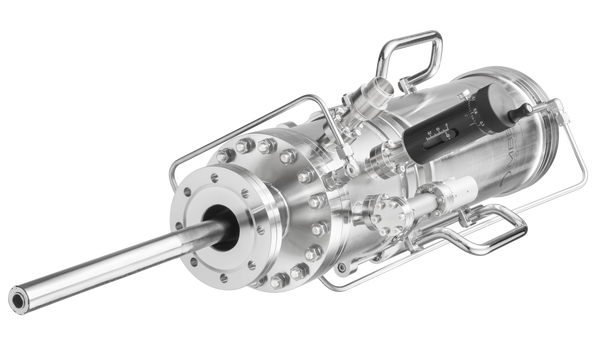

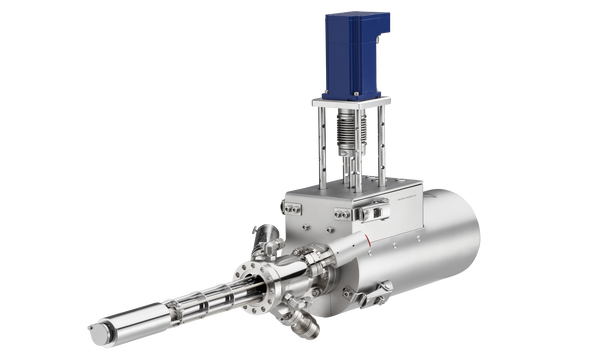

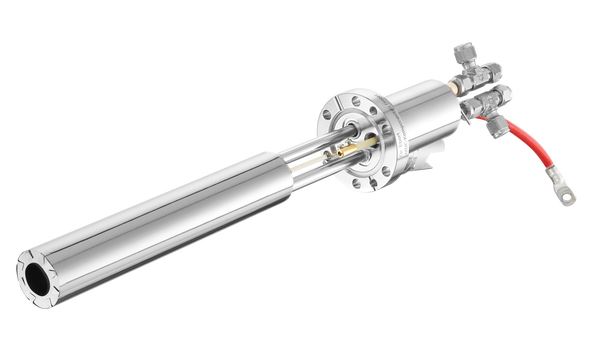

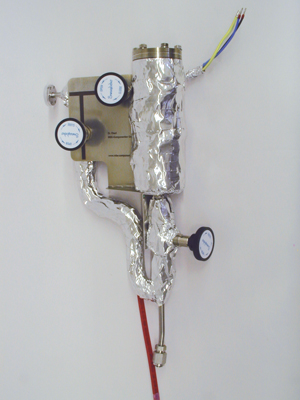

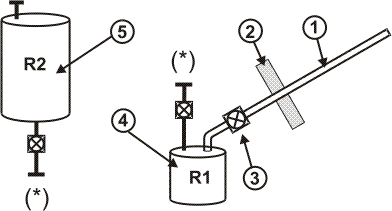

The AKS consists of the 150 cm 3 reservoir, precisely heated by a closed cycle heating thermostat, the heated valve and the heated injector unit which acts as interface to the UHV system. Both components, valve and injector, are independently heated electrically to avoid material condensation. An additional rotary shutter is available on request. The injector tube is water cooled on its outside to reduce the thermal load on the UHV system and to minimize outgassing during operation.

An easy and safe refilling procedure is provided by the use of a removable additional reservoir. This heatable refilling unit can be filled with reactive alkali metal source material within an inert gas floated external glove box, closed tightly and be mounted to the source. Thus, “quasi in-situ refilling” of the evaporator reservoir is made possible.

Application

The main purpose of the Valved Alkali Metal Source AKS is the controlled evaporation of elemental alkali metals like Cs or Rb from the heated reservoir inside the cell into a vacuum chamber under high to ultra-high vacuum conditions (i.e. pressures below 1x10-6 mbar).

Typical applications for the AKS are:

layer growth of Cs or Rb in MBE and surface science applications

MBE fabrication of alkali metal based electronic devices, e.g. infrared-sensitive photocathodes

Technical Data

| Filament type | 3 separate heater circuits (evaporator reservoir, valve & injector units) |

| Thermocouple | 2x type K Chromel/Alumel (injector/valve); 1x PT100 (evaporator reservoir) |

| Operating temperature | injector: 300°C; valve: 300°C; reservoir: 270°C |

| Outgassing temperature | injector: 300°C; valve: 300°C; reservoir: 270°C |

| Bakeout temperature | 200°C |

| Evaporator reservoir | 150 cm³ |

| Flux control | switchable valve unit |

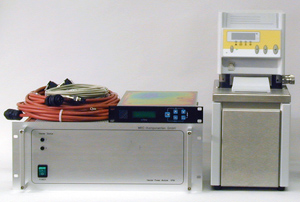

| Valve control | pneumatic operation, manual and remote control with TTL signal |

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Options | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|---|

| [cm3 ] | [mm] / [mm] | [W] / [A] | Product code | ||||

| AKS | 63* - | 150- | S**- | LxxxD57 | 2300 / 10 | HPM control unit |

* other mounting flange diameters on request ** rotary shutter possible on same flange (requires min. tube I.D. 63mm) *** specify UHV length L with order

Product code: e.g. AKS 63-150-S-L300D57 is a valved alkali metal source on DN63 CF flange with 150cm³ evaporator reservoir, shutter and UHV-length 300mm.