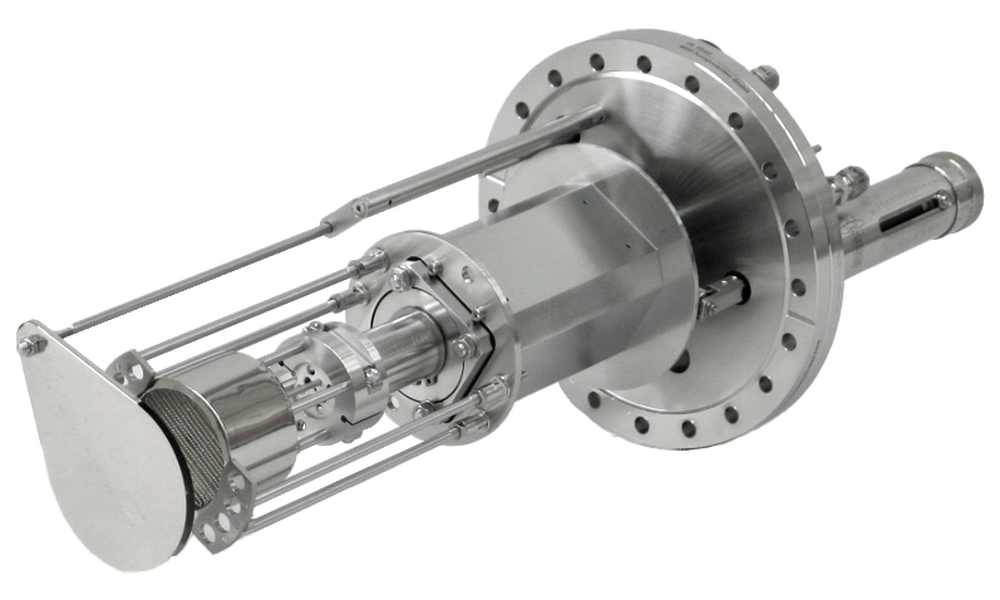

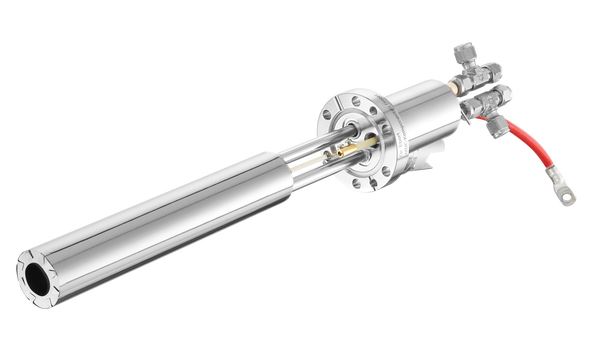

- Oxygen resistance option of the SH substrate manipulator

- Substrate temperatures up to 700°C with Ni-alloy heater; up to 900°C with noble-metal-alloy heater up to 900°C with SiC heater depending on oxygen partial pressure

- Pressure range from UHV up few mbar oxygen

- Water cooled ceramic bearings for continuous rotation

- Substrate sizes up to 6 inch

Introduction

MBE-Komponenten GmbH offers ovens, deposition stations or heated

stations which are resistant to oxygen or other reactive gas atmosphere.

The oxygen resistant option is indicated by the affix “-O”.

Selected shielding and construction materials are used for high

temperature applications in oxygen rich environments. Maximum substrate

temperatures of 700°C are possible using Ni-alloy heaters.

Noble-metal-alloy heaters and SiC heaters work for even higher substrate

temperatures of up to 900°C or in some cases even 1000°C depending on

the oxygen partial pressures during operation.

Due to the wide range of different applications and processes in oxygen rich environments a general recommendation of heater and construction materials is difficult. Please contact our specialists for more detailed recommendations to your specific application.

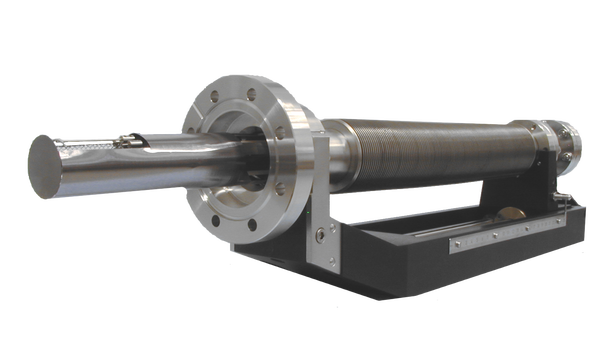

The specifications and options for the SH-O substrate manipulators are almost the same as for our SH models. They are:

- sample size up to 6"

- continuous substrate rotation

- water cooled ceramic bearings

- linear travel for substrate transfer

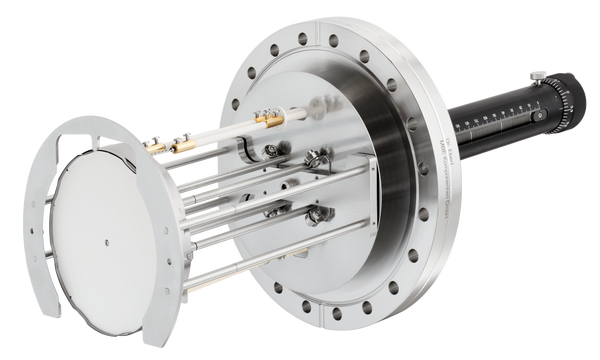

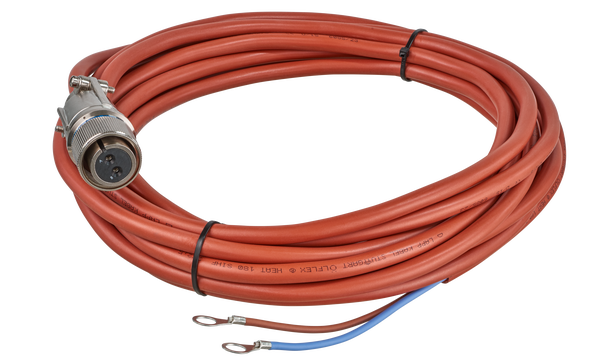

- thermocouple: Type K Chromel/Alumel (types R or S on request)

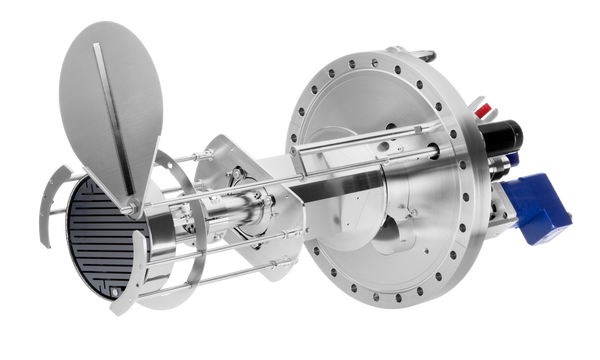

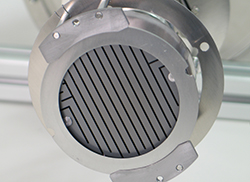

- integrated main shutter

- mask retainer

Application

SH-O substrate manipulators are used in oxygen rich environments (up to several mbar) or reactive gas atmosphere.

Attention:

Special care must be taken when compounds are operated at high

temperature and high pressure. In case of pressures above 10

-4 mbar the thermal conductivity of

gases has significant effects to heat transfer from heater to sample. It

is strongly recommended to contact our specialists when planning your

application.

| Heater type | Ni-alloy wire ( Ni ) or noble-metal-alloy wire ( Pt ), or SiC heater (S) |

| Thermocouple | Chromel/Alumel (type K); (others on request) |

| Wafer temperature | max. 700°C with Ni-alloy heater, max. 900°C with noble-metal-alloy and SiC heater |

| Bakeout temperature | 250°C |

| Electrical contacts | copper-free contacts for metal heater |

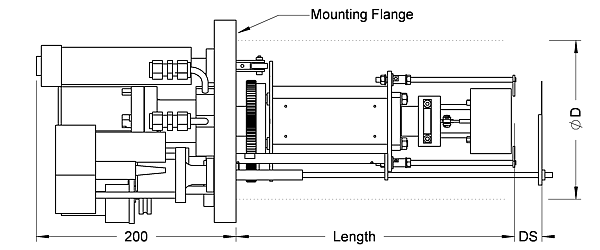

| Linear travel | 25 mm standard, 30-50 mm on request |

| Options | integrated main shutter ( S ), electrically insulated wafer holder with additional feedthrough for bias voltage ( B ), tantalum wafer holder ( T ) |

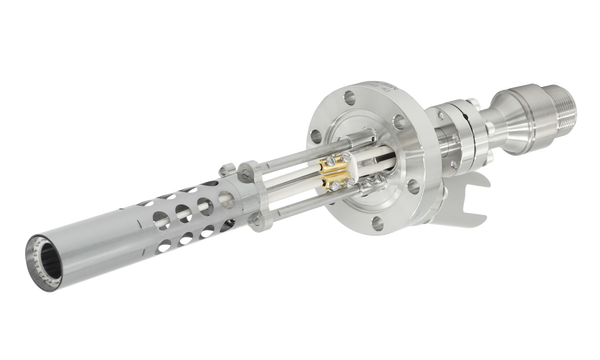

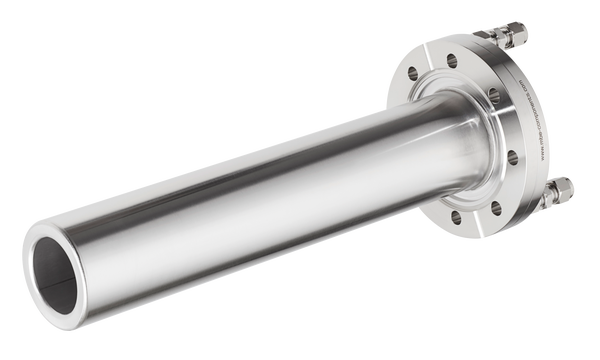

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .