- Controlled evaporation of volatile organic materials in research and industry

- Fabrication of OLED and organic photovoltaic cells, or spintronic devices

- Precise deposition with no temperature overshoot (stability to ±0.1K)

- Operating temperatures 50 - 700 °C

- 2 to 8-fold cluster arrays are offered

for co-deposition processes Datasheet

Introduction

Thermal evaporators of the OEZ type are dedicated to the controlled evaporation of all kind of volatile organic materials. They can be used for research or production of e.g. OLED devices, organic photovoltaic cells, molecular electronics, organic spintronics etc.

The OEZ product line denotes a group of diversified sources that are all characterized by excellent temperature stability, homogeneous temperature distribution within the crucible and a wide temperature range from 50 to 700 °C.

Several features and options make the OEZ a workhorse, suitable for research as well as industrial applications.

The PID controlled temperature stability of ±0.1 K allows precise control of the deposition rate. By design temperature hotspots and overshooting are effectively eliminated, which prevents decomposition of the organic material.

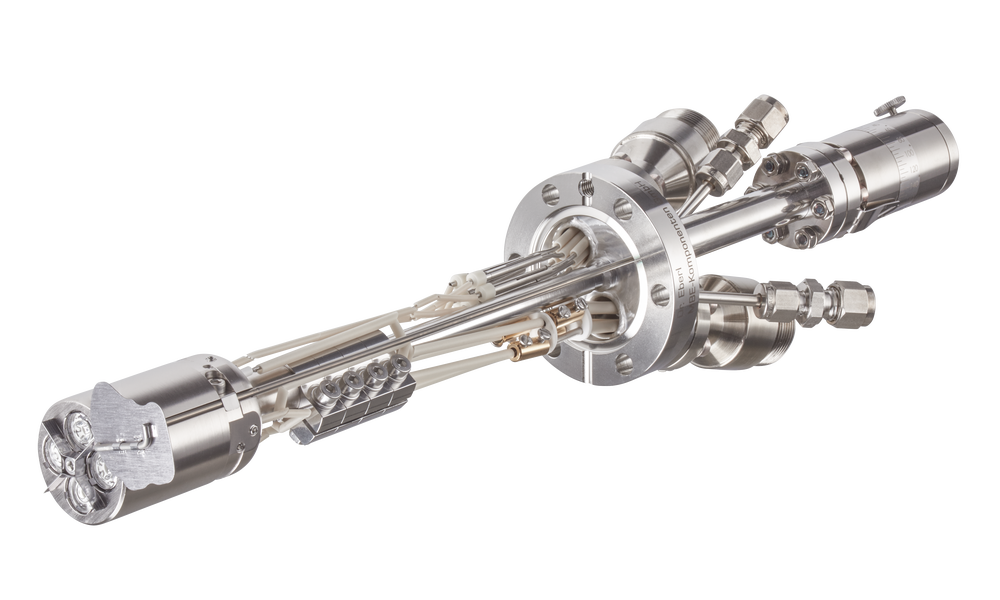

Quad cell OEZ 40-4x1-12-S: Four 0.2 cm3 crucibles on a single DN40CF (O.D. 2.75‘‘) flange, with integrated water cooling and rotary shutter

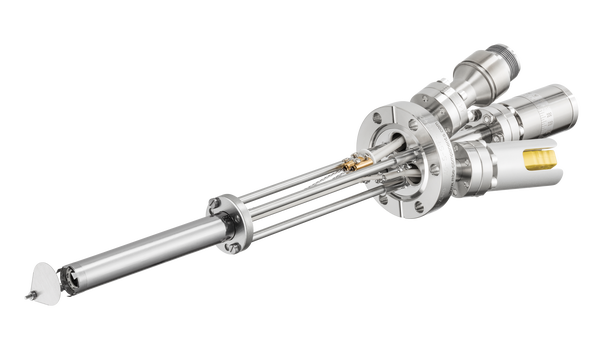

For the protection of sensitive research equipment during in situ experiments, specially designed nozzles for single and even dual cells are available (e.g., in situ co-deposition in UHV STM systems).

Optional beam shaping devices allow high film thickness homogeneity of the evaporated molecules along with an efficient material utilization. On request the plume shape can be projected by Monte Carlo method simulations.

Depending on the crucible size, OEZ cells can be used for evaporation of small amounts of expensive materials (for fundamental research applications) or deposition of large amounts of organics (in industrial production processes). Crucible replacement is easy and quickly accomplished. While quartz is the preferred material for the evaporation of organics, others like PBN, Alumina, or graphite are available as well.

Various models with single or multiple cells on the same flange ensure adaptability to miscellaneous organic thin film applications. The range of crucibles starts with 0.2 cm3 crucibles for small sample preparation in, e.g., surface science and reasonably ends with 25 cm 3 crucibles for samples of several inches diameter.

With the rugged and reliable design, inherent to every OEZ, long and stable operation - a basic requirement for industrial and reasearch use - is guaranteed.

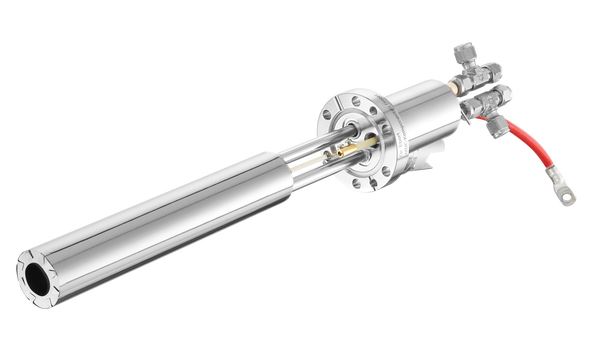

With integrated cell shutters both controlled sub-monolayer deposition and growth of thicker closed films is possible. An automated shutter actuation can be accomplished by applying electrical or pneumatic add-on shutter modules to the assembly, as shown in right-hand figure.

This cell is designed for horizontally oriented DN63CF (O.D. 4.5”)

ports.

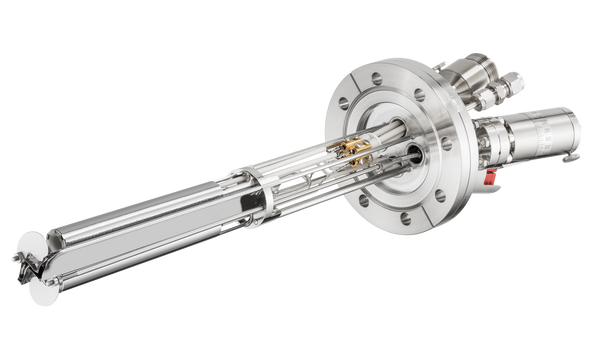

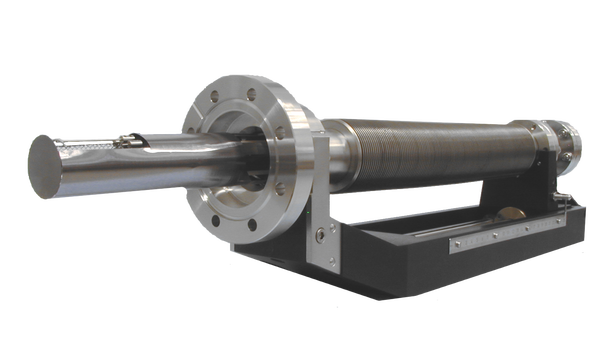

The OEZ 63-2x2-22-KKS-SF holds two 2 cm³ crucibles that can be heated

individually. Both crucibles are encapsulated in a water cooled copper

shroud. This encourages a fairly low thermal cross talk of the

crucibles. This cell is equipped with a linear push-pull shutter that

enables the user to open/close the crucibles independently.

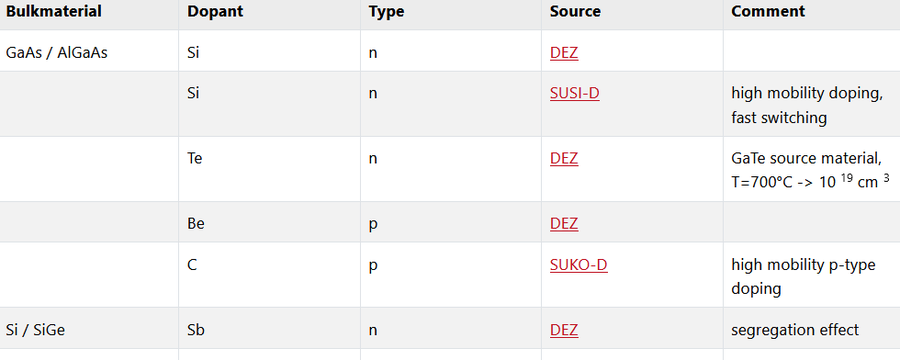

| Mounting flange | DN40 CF (O.D. 2.75’’) or larger; customized non-flange bulit cells on request |

| Filament | Tantalum wire heater (standard, hot-lip or dual filament configurations) |

| Temperature sensor | thermocouple NiCr/NiAl (Type K); others on request |

| Bakeout temperature | 250°C |

| Operating temperature | 50 °C - 700 °C |

| Outgassing temperature | 800 °C (1000 °C without crucible) |

| Crucible capacity | 0.2 cm³ up to 25 cm³ |

| Crucible material | Quartz; others (PBN, Alumina, etc.) on request |

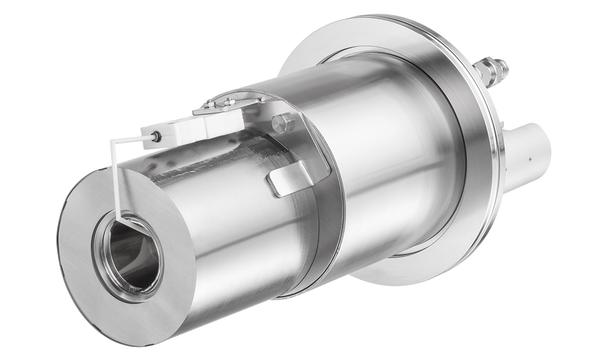

| Cooling | single cells: water cooling shroud (option K

) dual and quad cells: integrated water cooling between the heaters |

| Shutter | integrated rotary shutters ( S ) |