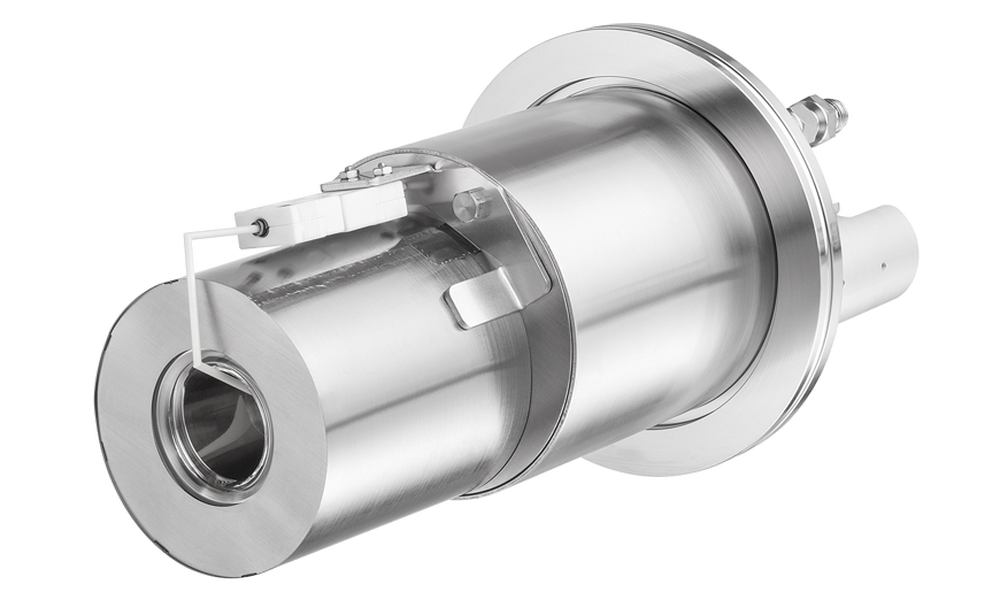

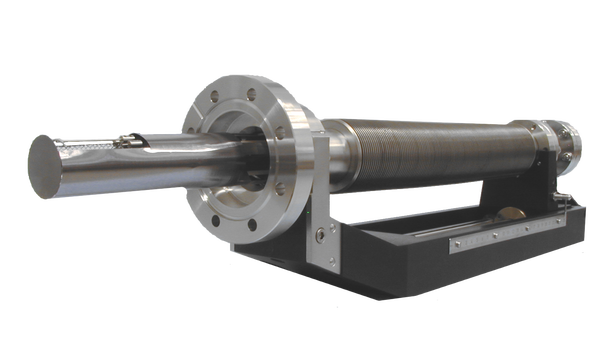

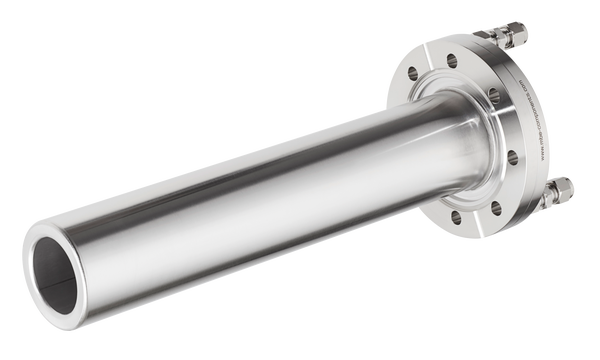

- Flange size DN 100 ISO-K

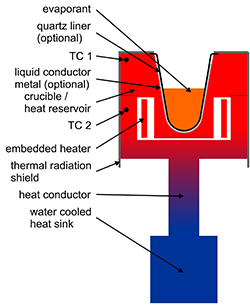

- Patented Thermal Conduction Cooling (TCC)

- Ideal for evaporation of organic materials for PV, display and OLED applications

- Fast and precise temperature control

- Temperature range 15-400°C

- Fully UHV and MBE compatibility

Introduction

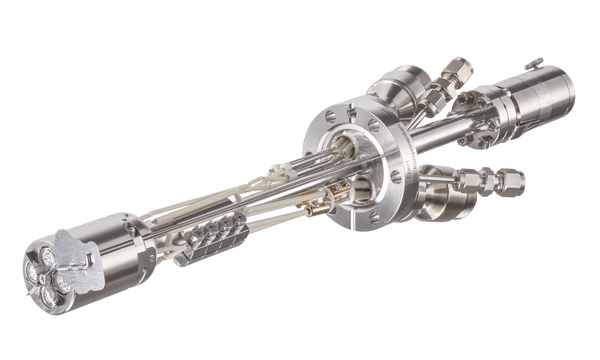

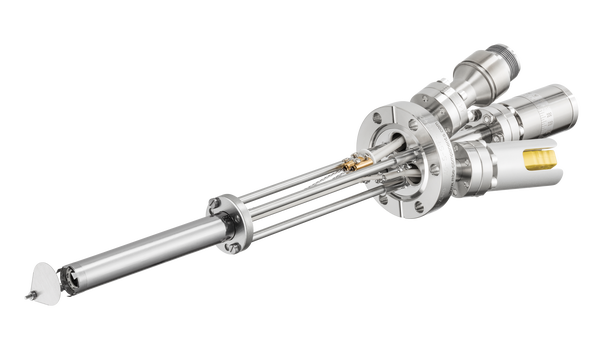

The Organic Material Effusion Cell OME is specially designed for the evaporation or sublimation of high vapor pressure materials, notably sensitive organic substances, at operating temperatures up to 400°C. It can likewise be used for other materials typically evaporated at very low temperatures, e.g. alkali metals. Due to its patented Thermal Conduction Cooling with encapsulated heater unit, the OME offers drastically improved operation properties below the lowest temperature limit of common Knudsen-type effusion cells.

As an option we offer the TCC concept for the OME 100-75, which involves a liquid metal used as a thermal conductor that provides a direct thermal connection between crucible and heat reservoir, leaving no isolating voids.

Conventional effusion sources show a poor cooling efficiency, due to the

T4-dependency of emitted radiation power, rendering precise temperature

control below 150°C very difficult.

The OME with the TCC concept uses the linearity of the heat transfer

between a heated reservoir and a cooled heat sink to obtain a high

cooling rate even at very low operating temperatures. Rapid cooling

down, low thermal time constants and a stable temperature control are

thus achieved.

Despite its larger thermal mass the cooling rate of the TCC cell is much

higher at low temperatures and reaches up to 10°C/min even at 70°C

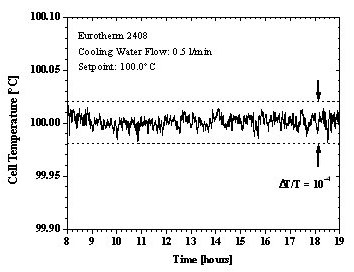

The diagram below shows the excellent long term temperature stability of the OME with TCC concept. During a period of 10h of operation the temperture does not fluctuate more then ± 0.02 K

| Mounting flange | DN100 ISO-K or larger |

| Length in vacuum | 180-400nm |

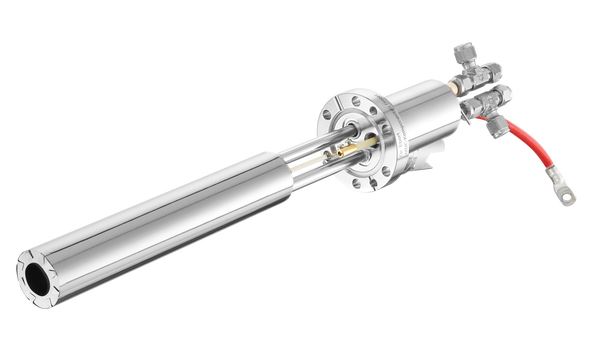

| Heating system | Encapsulated Ta-wire heater with patented TCC-technique |

| Temperature sensor | NiCr/NiAl (type K) thermocouple |

| Bakeout temperature | 250°C |

| Operating temperature / stability | 15°C1) - 400°C2) ; <±0,02K |

| Cooling | integrated water cooled heat sink; water flow > 0.5l/min |

| Crucibles | 18 cm³ larger sizes on request |

| Crucible Material | Cu, Ni, Au, Quartz (Liner) |

| Crucible / Liner | 180-00-612 / 480-00-028 |

| max. Power / Current | 400W, 12A, Power Supply: PS 40-19 |

| Shutter | Integrates rotary shutter ( S ); tight sealing shutter ( TS ) |