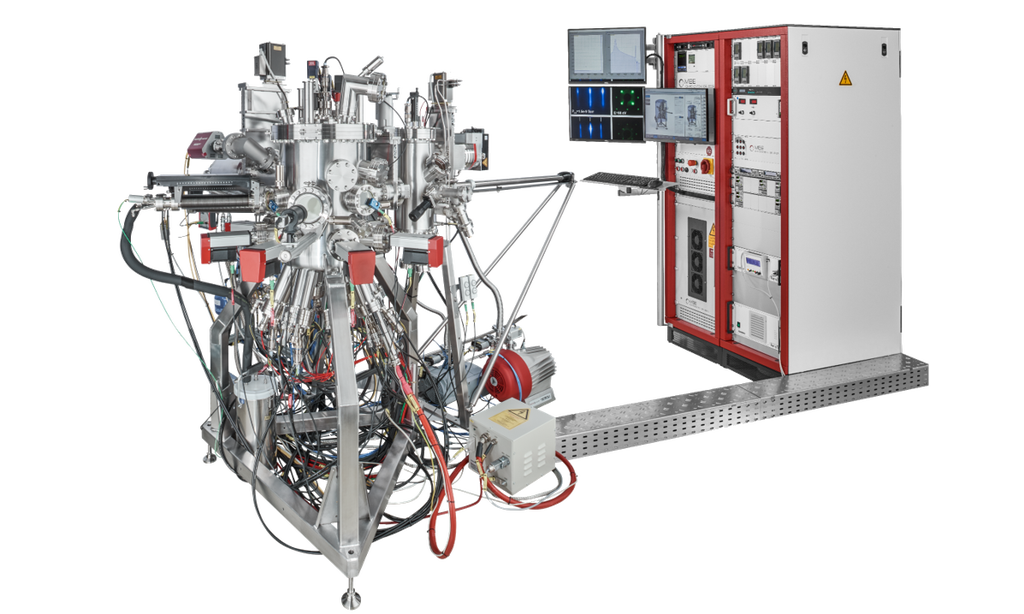

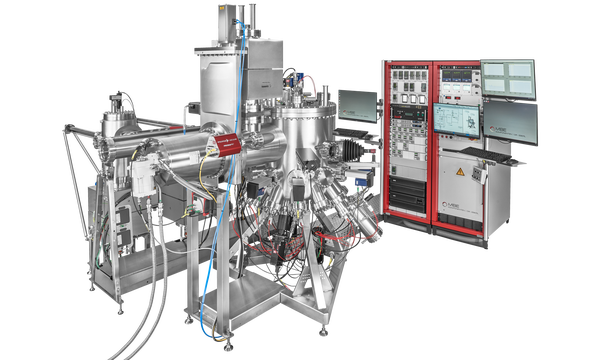

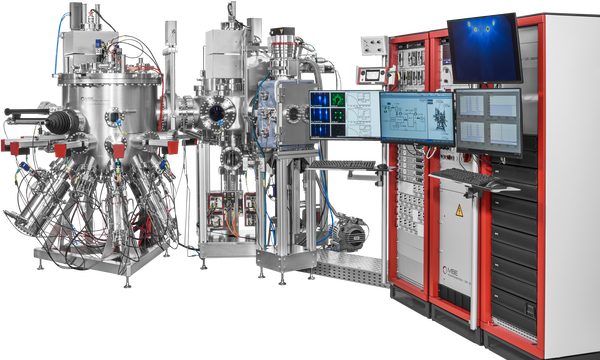

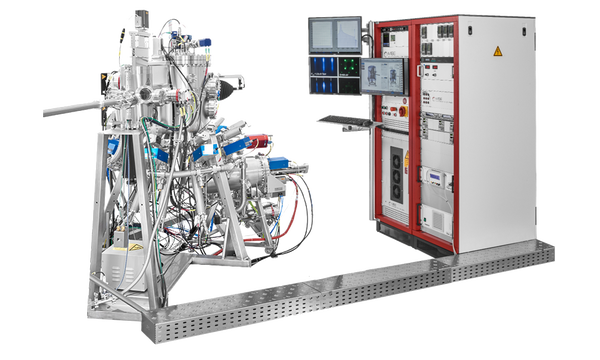

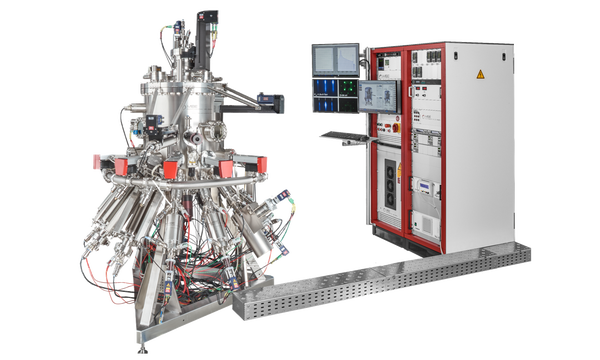

Compact III/V, II/VI or other material MBE system

- Compact and versatile MBE system for R&D

- Applications: III-V, II-VI or Oxide-MBE

- Up to 8 source ports, various options including e-beam evaporators

- Wide range of source options

- Horizontal substrates up to 2''

- Effective UHV pumping system

- Ease of use and maintenance

- In-situ characterization capability

- Professional support by PhD MBE experts

General Information

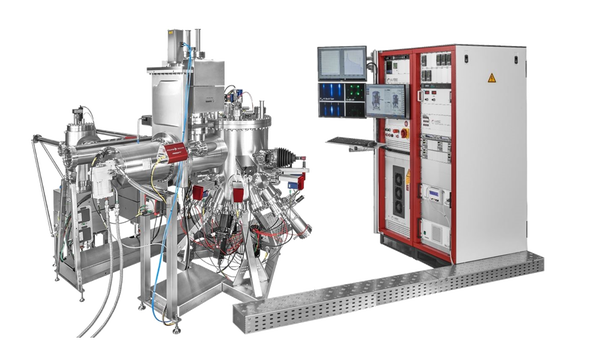

The OCTOPLUS 350 system is ideally suited for III-V, II-VI and other compound semiconductor material applications. The OCTOPLUS 350 system can be easily adapted to small wafer segments as well as to 1 or 2 inch wafers. A version with a manipulator for flag shaped scientific sample plates is also available. The field-proven vertical chamber design of the OCTOPLUS 350 plus various state-of-the-art components allow layer by layer precise MBE growth.

Outstanding features of the OCTOPLUS 350 are the high reliability and versatility of the system and its compactness. These features make the OCTOPLUS 350 system particularly suited for applications in research and development. Nonetheless specific production processes are also covered.

The standard version of the OCTOPLUS 350 comprises 8 source ports with 4.5 inch (DN63CF) flange size. The DN63CF effusion cell ports are equipped for use with a linear shutter system.

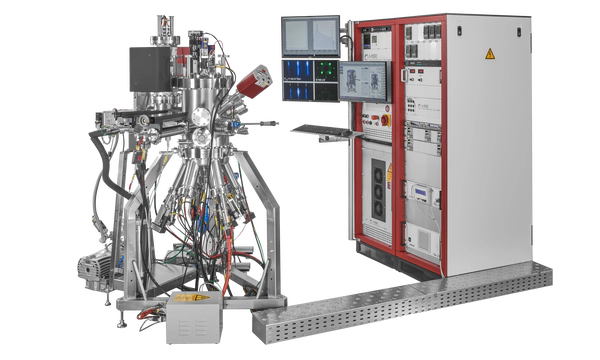

A version with horizontally mounted 6-pocket electron beam evaporator and 4xDN63CF ports allows research on layers containing high temperature materials such as W, Ta, Nb, Mo, Pt, that can be best evaporated with an electron-beam evaporation. This can be used for metallization or growth of compounds such as transition metal dichalcogenides.

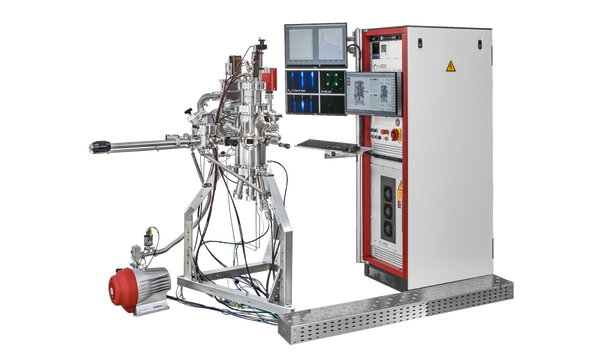

A rapidly pump-down load lock chamber with a horizontal working transfer rod system allows easy substrate introduction without breaking the vacuum of the MBE chamber.

We provide different kinds of effusion cells, valved cracker sources, gas sources and substrate manipulators according to your requirements. A well-manageable in-situ characterization is obtained by using beam-flux-gauges, RHEED systems or quadrupole mass analyzers (QMA). The system comes with a MBE growth software that controls all shutters, cell- and manipulator temperatures, as well as related process parameters such as chamber pressure and cryopump temperatures. Maximum operation reproducibility and safety is guaranteed.

We are happy to discuss your MBE system specifications and give competent advice for your application. Do not hesitate to contact us.

The OCTOPLUS 350 is in use in leading laboratories. On demand we transmit a detailed list of references.

Options for OCTOPLUS 350

- Additional load lock or buffer chambers, interface to UHV suitcase

- Effusion cells, source clusters, valved or gas sources, manipulators, power supplies and control units

- OCTOPLUS 350 EBV model with six-pocket electron beam evaporator and 4xDN63CF effusion cell ports

- Version for dedicated use with scientific sample plates and EBV+6xDN40CF source flanges for compact sources with integrated rotary shutters

- Pumping system (ion getter pumps, turbopumps, cryopumps etc.)

- Software / hardware control system

- In-situ characterization tools, e.g. ion gauge, Quartz Crystal Microbalance (QCM), pyrometer, RHEED, QMA

Technical data

| Size of deposition chamber | 350 mm I.D. |

| Base pressure | < 8x10-11 mbar |

| Pumping | cryopump, turbopump, TSP or ion getter pump |

| Cooling Shroud | LN2 or other cooling liquid on request |

| Substrate heater temperature | up to 800°C, 1000°C or 1400°C |

| Substate size | up to 2" diameter |

| Bakeout temperature | up to 200°C |

| Source ports | up to 8 ports DN63CF |

| Source types | effusion cells, e-beam evaporators, sublimation sources, valved cracker sources, gas sources |

| Shutters | soft-acting linear or rotary shutters |

| In-situ monitoring | ion gauge, QCM, pyrometer, RHEED, QMA |

| Sample transfer | linear transfer rod, manual or semi-automatic |

| Load lock | magazine with 6 substrates turbo-pumped |

| MBE control software | Tiny Tusker |

| Service | system installation and acceptance testing |

| MBE training | by MBE experts |

Examples for applications and corresponding sources

| Effusion Cells WEZ , NTEZ OME , HTEZ | Sublimation Sources SUKO , SUSI HTS , DECO Valved Sources | VACS , VGCS , VSS , VTCC , TCC Plasma Sources | FMP E-Beam | Evaporators EBVV | |

| III/V | Ga, In, Al, B | C, Si doping | As, P, Sb | ||

| II/VI | Zn, Cd, Be | S, Se, Te | N-doping | ||

| IV | Ge, Sn, Pb | B, P, Sb doping | Si, Ge | ||

| GaN | Ga, In, Al | N | |||

| Metals | Cu, Al, Ni, Co, ... | Pt, Ta, Pd, Mo, W | |||

| Topological Insulators | Ge, Sn, Te, Bi, GeSb | Se, Te | B | ||

| Graphene / Silicene | C, Si | ||||

| Oxides | Fe, Ni, Mn, Bi, Eu, Ga, ... | O | |||

| Thin Film Solar Cells | Cu, Ga, In, Zn, NaF, Fe, Sn | S, Se |

Trusted expertise since 1990

The product range and quality of Dr. Eberl MBE-Komponenten GmbH benefit from many years of active research experience of its team members.

We now look back on about 35 years of development and manufacture of complex systems and components for multiple tasks in the applied research and production of compound semiconductor materials. Each product is assembled and carefully tested in-house by our MBE experts.