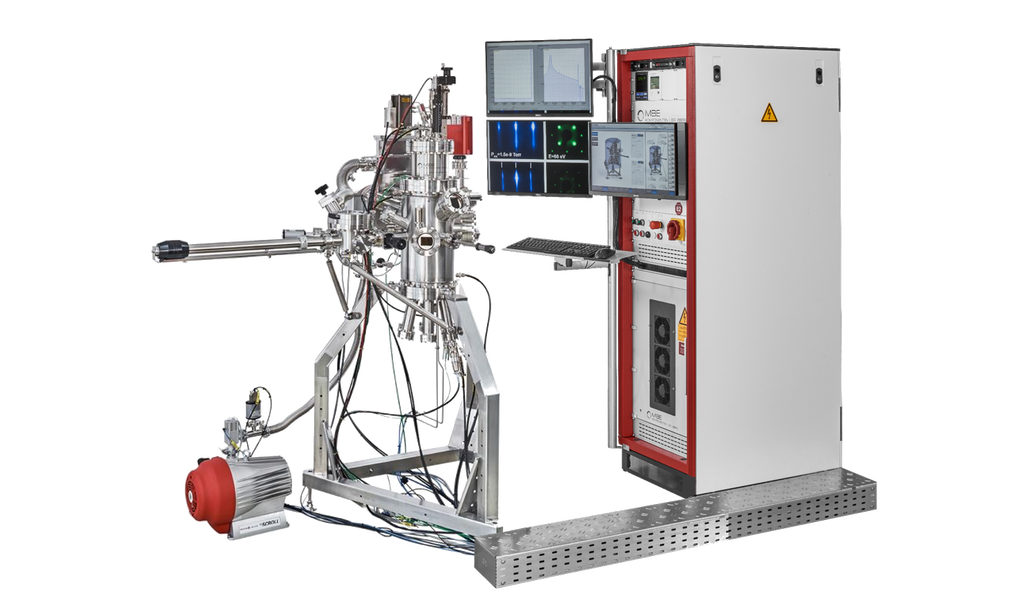

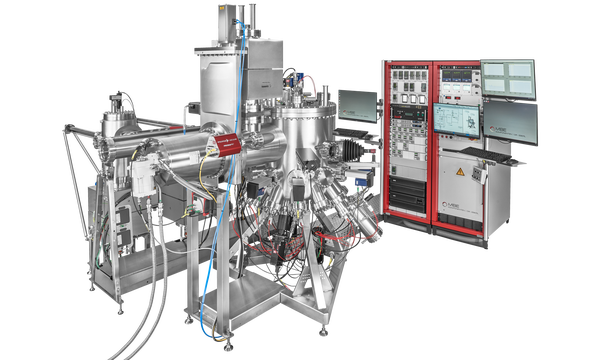

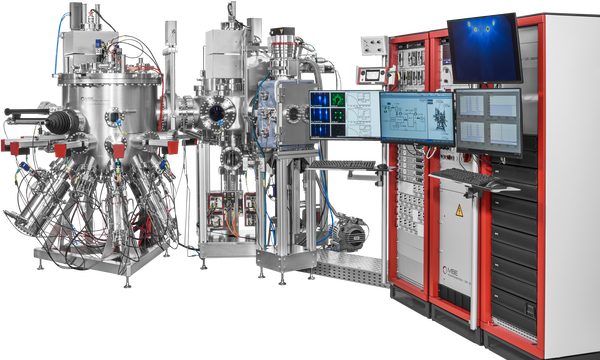

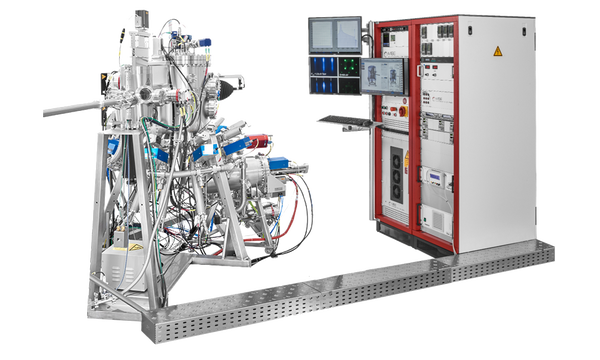

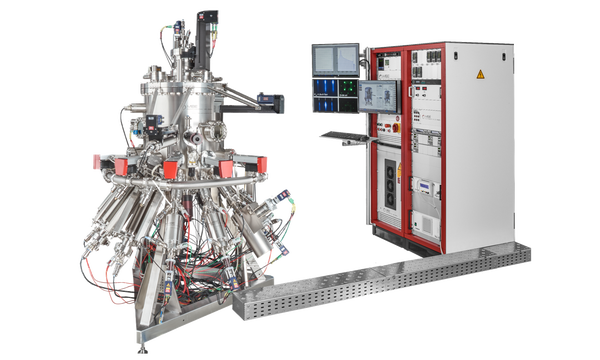

Compact mini MBE system for surface science samples

Compact and versatile research MBE system with ultra-small footprint

- Applications: heat novel materials research and UHV surface sience

- 6 source ports DN40CF (O.D. 2.75’’)

- Wide range of source options

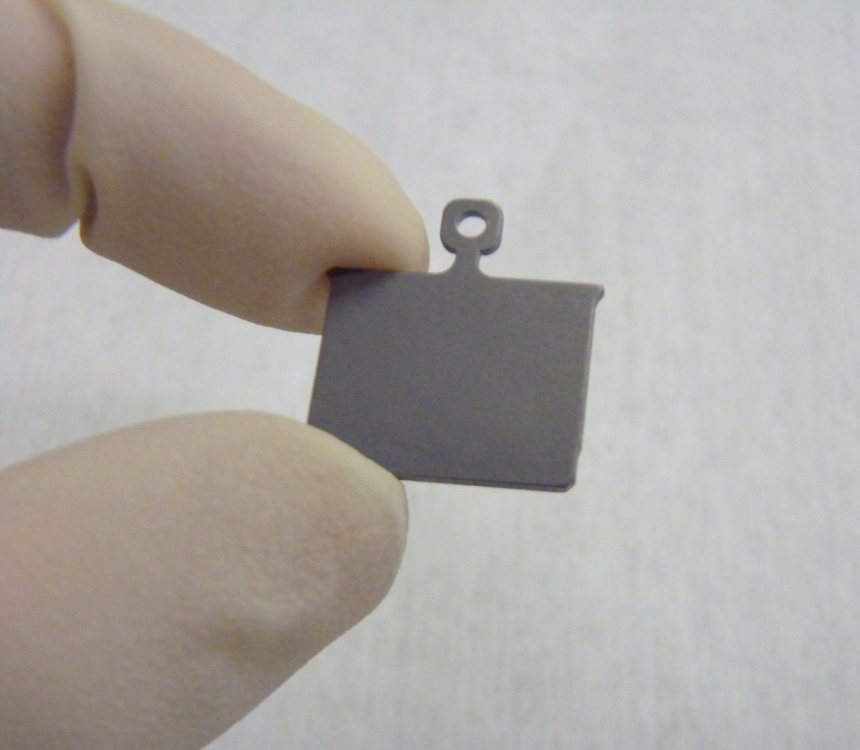

- Sample size : flag style scientific sample plate 10x10 mm2

- Effective UHV pumping system

- Water cooled chamber body, no LN2 infrastructure needed

- Low energy consumption, economic operation, minimal site requirements

- In-situ monitoring capability

- Professional support by PhD MBE experts

General Information

The OCTOPLUS 200 system is ideally suited for material deposition on small samples. It provides good access and easy operation and maintenance. The chamber design of the OCTOPLUS 200 plus various state-of-the-art components allow layer by layer precise MBE growth.

Outstanding features of the OCTOPLUS 200 are the high reliability and versatility of the system and its small footprint. These features make the OCTOPLUS 200 system particularly suited for applications in research and development. Its ultra compact footprint allows it to be integrated in tight laboratory spaces with other existing in-situ UHV surface analysis equipment.

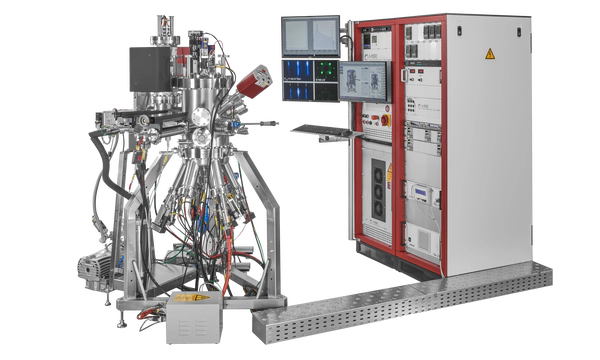

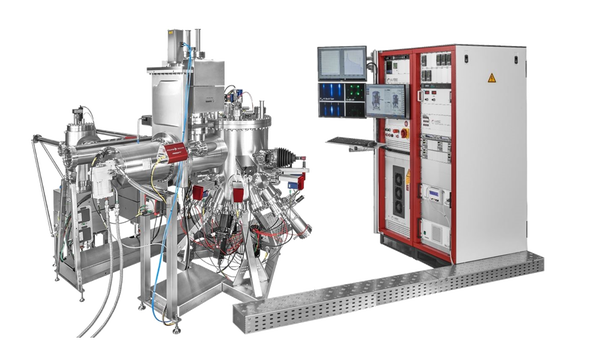

The standard version of the OCTOPLUS 200 comprises six ports with DN40CF (O.D. 2.75’’) flange size. By using Source Clusters many more source materials can be integrated into the system. A rapid pump-down load lock chamber with a horizontally working transfer-rod system allows the user an easy substrate introduction without breaking the vacuum of the MBE chamber. The transfer system can be easily adapted to integrate with other existing surface analysis equipment for fundamental research, e.g. at synchrotron facilities.

We provide different kinds of effusion cells, valved cracker sources, gas sources and substrate manipulators according to all our customers’ requirements. A well-manageable in-situ characterization is obtained by using beam-flux-gauges, pyrometers, RHEED systems or quadrupole mass analyzers (QMA).

We are happy to discuss your MBE system specifications and give competent advice for your application. Do not hesitate to contact us.

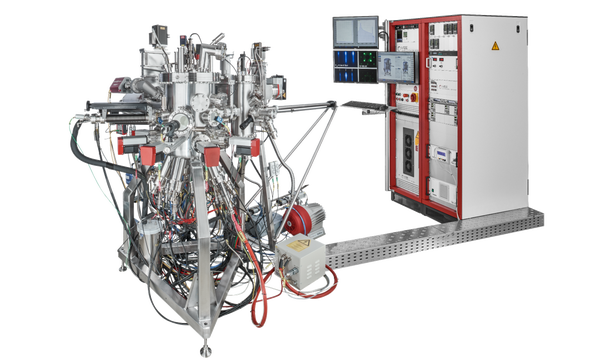

Options for OCTOPLUS 200

- Additional load lock or peparation chambers

- Wafer transfer system

- Effusion cells, source clusters, electron beam evaporators, cracker and valved cracker sources, manipulators, power supplies and control units

- Pumping system (ion getter pumps, turbopumps, cryopumps etc.)

- Control system

- In-situ characterization tools, e.g. ion gauge, Quartz Crystal Microbalance (QCM), pyrometer, RHEED, QMA

Technical Data

| Size of deposition chamber | 200 mm I.D. |

| Base pressure | < 2x10-10 mbar |

| Pumping | turbopump, ion getter pump and TSP |

| Cooling Shroud | water cooling |

| Substrate heater temperature | up to 1200°C, continuous substrate rotation |

| Substate size | scientific sample plates (10x10 mm2) |

| Bakeout temperature | up to 150°C |

| Source ports | 6 ports DN40CF |

| Source types | effusion cells, mini e-beam evaporators, sublimation sources, valved cracker sources, gas sources, source clusters |

| Shutters | soft-acting rotary shutters |

| In-situ monitoring | ion gauge, QCM, pyrometer, RHEED, QMA |

| Sample transfer | linear transfer rod (manual) |

| Load lock | magazine with 10 flag-shaped scientific substrates turbo-pumped |

| MBE control software | Tiny Tusker |

| Service | system installation and acceptance testing |

| MBE training | by MBE experts |

Examples for applications and corresponding sources

| Effusion Cells WEZ I NTEZ I OME I HTEZ | Sublimation Sources SUKO I SUSI I HTS I DECO | Valved / Cracker Sources VTCC I TCC I VSS | Plasma Sources | |

| III/V | Ga, In, Al | C, Si doping | As, P, Sb | |

| II/VI | Zn, Cd, Be | S, Se, Te | N-doping | |

| IV | Ge, Sn, Pb | B, P, Sb doping | ||

| GaN | Ga, In, Al | N | ||

| Metals | Cu, Al, Ni, Co, Pb... | |||

| Topological Insulators Thermoelectrics | Ge, Sn, Te, Bi, GeSb | Se, Te, Sb, alkali metals | ||

| Oxides | Fe, Ni, Mn, Bi, Eu, Ga, ... | O | ||

| Thin Film Solar Cells | Cu, Ga, In, Zn, NaF, Fe, Sn | S, Se |

Trusted expertise since 1990

The product range and quality of Dr. Eberl MBE-Komponenten GmbH benefit from many years of active research experience of its team members.

We now look back on about 35 years of development and manufacture of complex systems and components for multiple tasks in the applied research and production of compound semiconductor materials. Each product is assembled and carefully tested in-house by our MBE experts.