- Large capacity up to 55 kg Cu

- Very high flow rate up to 220 g/h for Cu

- Long lifetime

- Designed for easy maintenance

- Proprietary encapsulation of heater and shielding

- Simple ingot handling

- High material efficiency through beam shaping insert

- Encapsulated thermocouple

- Pyrometeric temperature control option

- Well proven in the field Datasheet

Introduction

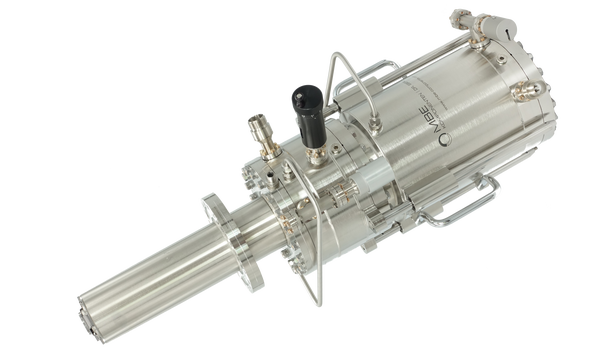

Our PEZ-series sources are proven technology for industrial production of CuInGaSe (CIGS) thin film solar cell co-deposition. They are well proven in the field.

The unique design of the source provides exceptional performance. In every detail the source has been constructed for a long life time and easy and fast maintenance. Our proprietary and patented encapsulation of the inner source and careful selection of materials and its combination ensures virtually no degradation. The sophisticated modular setup of the source with easily releasable fastenings allows for rapid service routines and part replacements if necessary.

The robust carbon based dual filament heater is designed for long-term application in production.

There are different crucible sizes available to fit several production relevant demands. Standard sizes are 2000ccm or 4000ccm, other sizes can be provided on request ( contact us).

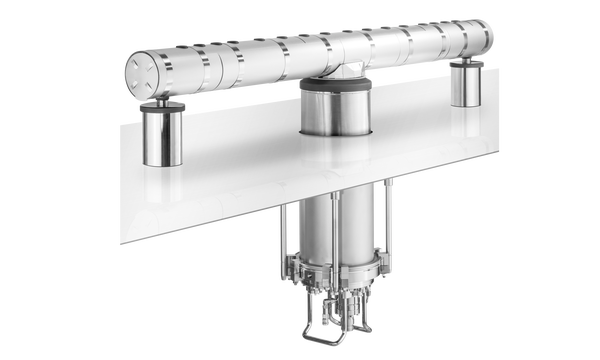

The source is mounted in a cooling shroud to minimize thermal input to the chamber. The in chamber length of the source is variable and can be adjusted by an adapter flange.

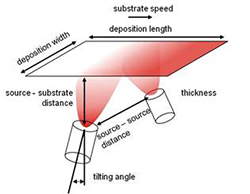

The use of a beam shaping insert enables unique evaporation profiles for enhanced material efficiency and process optimization. The customization is supported by our proven simulation technology.

MBE-Komponenten provides support in the design of customer-specific research or production systems in order to achieve customized source geometry, optimized for specified layer uniformity and material utilization.

Co-evaporation processes can be simulated on request. The simulations are based on geometric and Monte Carlo method calculations. Typical results include the lateral layer thickness distribution and material composition for multiple material co-deposition processes on semiconductor wafers as well as on large area substrates. For more details see Simulation.

Applications

Main applications of the PEZ-G series evaporators are:

- CIGS thin film solar cell

- Kesterite thin film solar cell deposition

- Metallization processed in PVD systems

- OLED or organic solar cell deposition

Technical data

| Model | PEZ-G 200 | PEZ-G 150 | PEZ-G 100 | PEZ-G 63 | ||

| nominal crucible volume (other sizes on request) | 10000 ccm | 4000 ccm | 2000 ccm | 800 ccm | 160 ccm | |

| base charge volume1) | 6000 ccm | 2400 ccm | 1200 ccm | 480 ccm | 100 ccm | |

| operation temperature | up to 1500°C | up to 1500°C | up to 1500°C | up to 1500°C | up to 1500°C | |

| evaporation rate (for Cu)2) | max. | up to 220 g/h | up to 130 g/h | up to 70 g/h | up to 35 g/h | up to 10 g/h |

| typical | 65 g/h | 35 g/h | 20 g/h | 10 g/h | 3 g/h | |

| power supply (for Cu)2) | top heater | 10000 W | 5200 W | 5000 W | 2400 W | 1500 W |

| bottom heater | 5000 W | 3300 W | 2400 W | 1500 W | 750 W | |

| typical power consumption (for Cu)2) | top heater | 10000 W | 5200 W | 3300 W | 2000 W | 600 W |

| bottom heater | 2000-3000 W | 1200-1500 W | 600-1100 W | 400-600 W | 150-220 W | |

| flange sizes3) | water cooling | O.D.12" (DN250CF) | O.D.10" (DN200CF | O.D.8" (DN150CF) | O.D.6" (DN100CF) | |

| evaporation source | O.D.10" (DN200CF) | O.D.8" (DN150CF) | O.D.6" (DN100CF) | O.D.4,5" (DN63CF) | ||

| water cooling | cooling shroud, base flange, electric feedthrough | cooling shroud | ||||

| water flow rate | 270 l/h | 150 l/h | 90 l/h | 75 l/h | 30 l/h | |

Results from large scale CIGS production systems indicate the following:

- Stable operation over several days

- Very good material efficiency >40% due to beam shaping

- Excellent homogeneity of film composition on large glass substrates [Cu]/([In]+[Ga]): <± 2.5 %

- Excellent CIGS material quality:

- High efficiency of solar cells out of full scale module production

- Low cost of ownership: long lifetime of heaters and shieldings

Please contact us for more detailed informations.