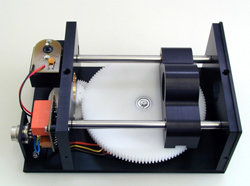

Soft-acting linear motion mechanism

Shutter action time 0.2 sec (open-close)

Magnetically coupled feedthrough

Feedthrough on DN40 CF flange

30 to 100 mm linear travel

Feedthrough UHV compatible and bakeable up to 300°C

Introduction

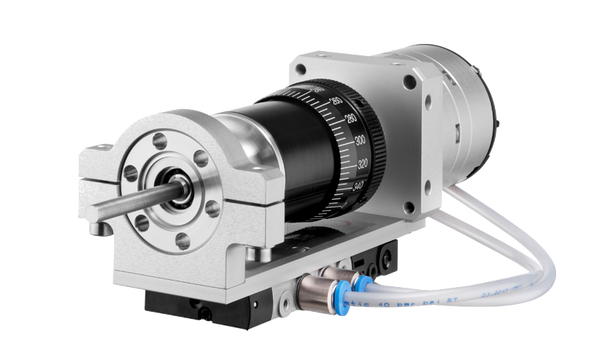

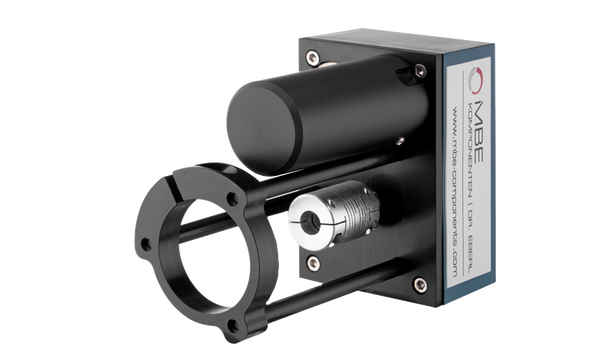

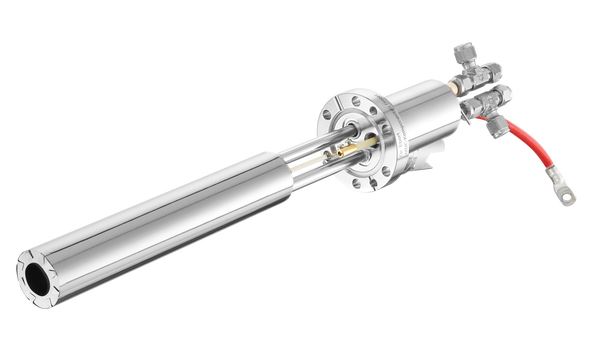

The Soft-acting Linear Shutter Module - LSM - consists of a soft-acting linear motion mechanism, driven by an electric motor and acting upon a magnetically coupled linear motion feedthrough.

The soft-action arises from a sinusoidal linear velocity profile of the external magnet. It reduces particle generation and greatly increases shutter lifetime under UHV conditions. Fast shutter action times of less than 200ms (open-close) are achieved without mechanical shock and with minimum vibrations. This high shutter speed easily allows for sub-monolayers control of epitaxial growth. The LSM acts in a digital manner, only moving the shutter between its two end-positions (open - close). Intermediate positions cannot be set by the drive unit.

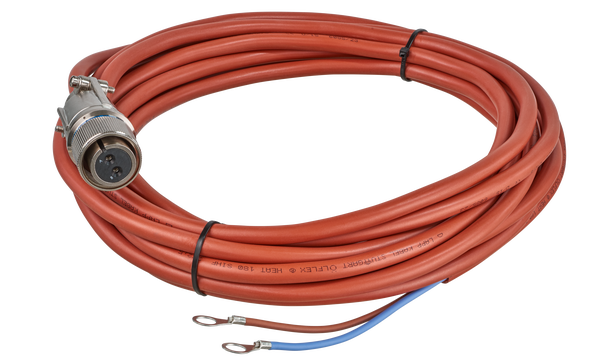

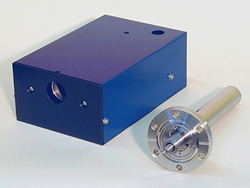

Automated shutter action is obtained with the LSM connected to our shutter control unit SCU. The shutter control unit provides the power to the motor (24V DC) and controls the shutter action. Position feedback indicators show the actual shutter status. The SCU allows manual and remote shutter control. The linear travel length is factory-preset on the drive unit. It can range from 30 mm up to 100 mm.

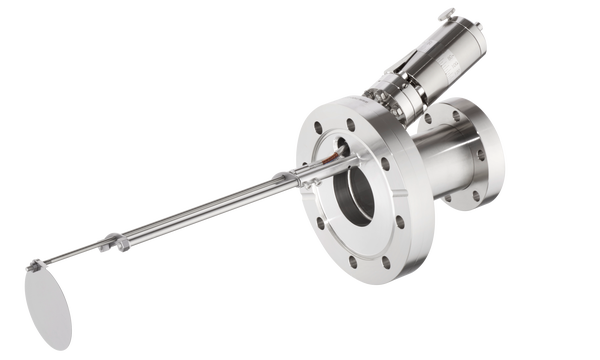

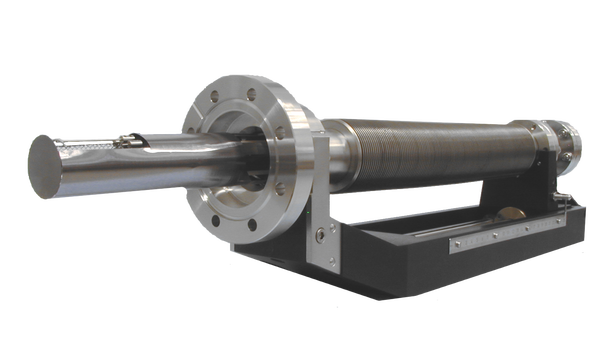

The magnetically coupled linear feedthrough is mounted on a DN40 CF base flange and has a stroke of 100 mm. Linear ball-bearings guide the shaft, which delivers 20 N of linear force in combination with the external ring magnet (contained in the drive module). The shaft cannot be rotated. A purely manual version of the feedthrough is available on request.

Application

The LSM is ideally suited for use with linear motion shutters, e.g. for

our electron beam evaporator EBV. We recommend using the LSM 40 in

combination with our shutter control unit SCU.

The standard shutter speed is 0.2 s (open - close). For special

applications we provide slower versions with shutter speeds of about 0.5

s or 1 s between the end positions. This is often desired when heavy

shutter assemblies, such as shutter plates lined with crystalline

silicon plates, are moved. The slower speed further reduces the chance

of particle generation.

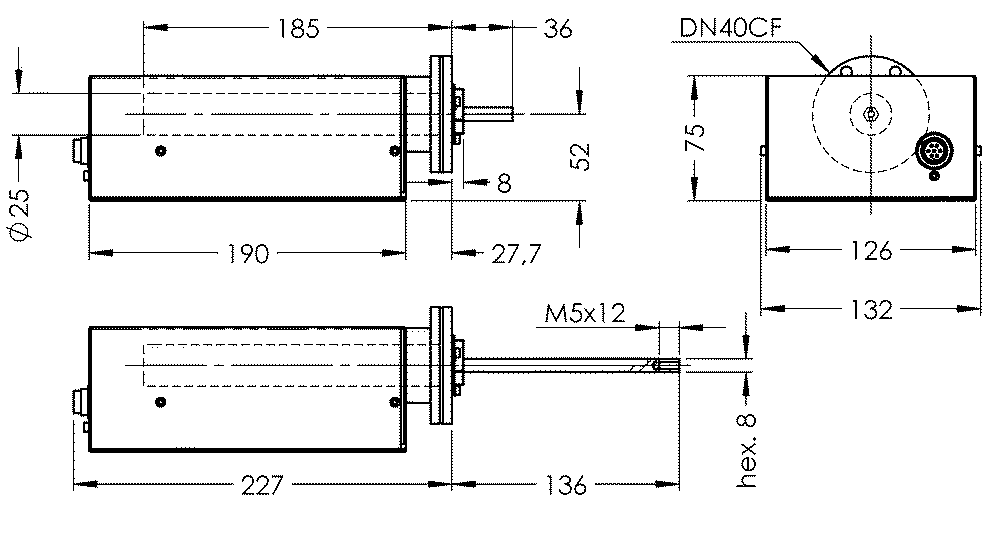

Dimensions