- Precise substrate rotation control

- Brushless motor for high reliability and constant speed under variable load

- Manual or remote operation

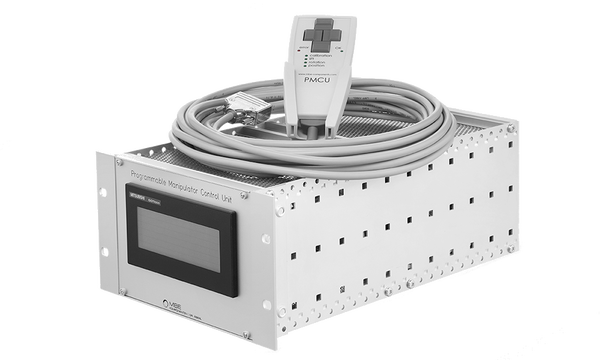

- 19" rack system compatible

Introduction

The Manipulator Control Unit - MCU provides the power for the motor, which rotates the substrate or substrate holder of a manipulator. Manual and remote control of rotation speed, direction of rotation and start/stop is possible. The control signals can be set manually, with TTL signals or with external relays. For remote setting of the rotation speed an analogue signal can be used optionally.

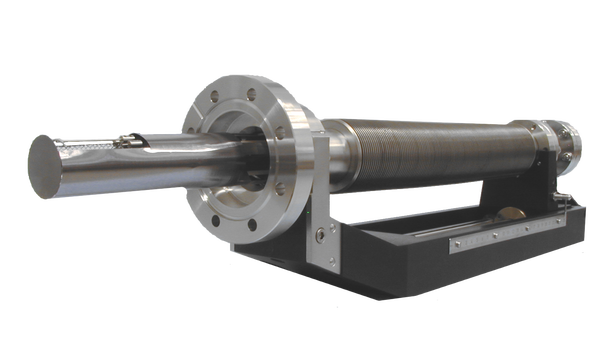

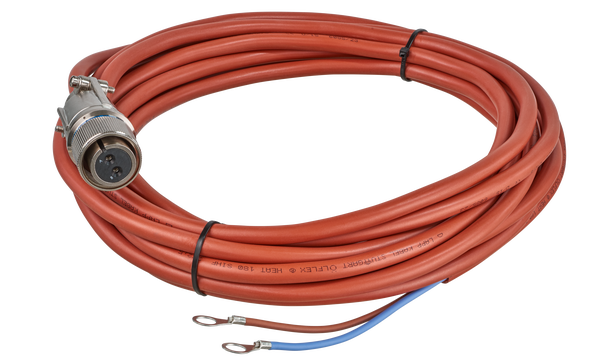

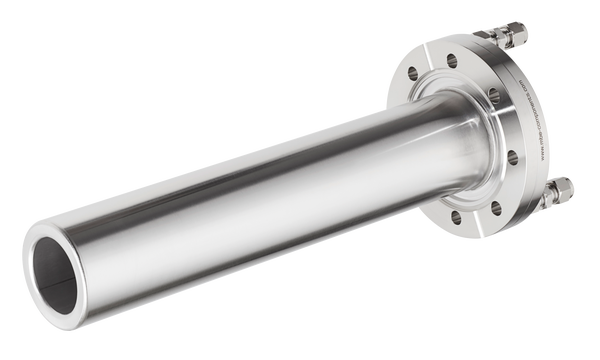

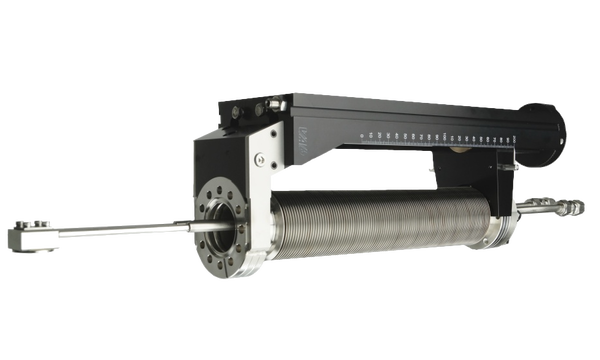

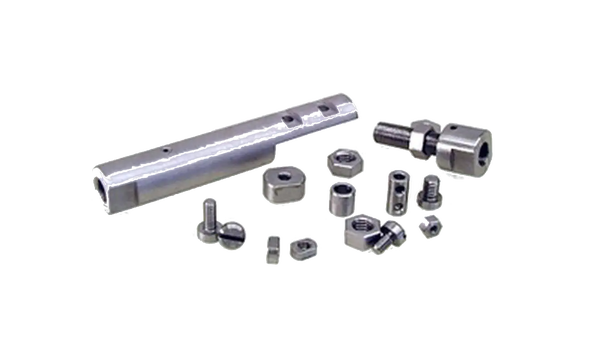

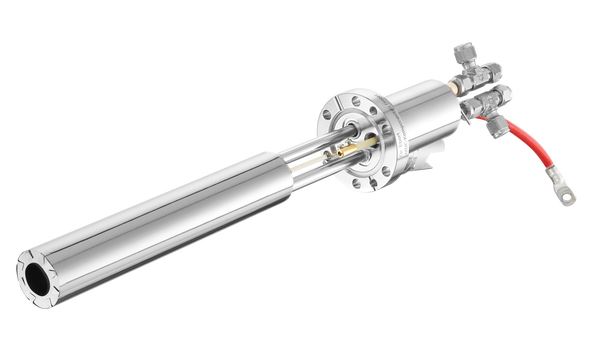

The MCU is delivered together with a matching brushless motor for long-life operation and with a motor mount. The motor mount is designed to be clamped onto the DN16 CF flange of our magnetically coupled rotary feedthrough MRD 16. The feedthrough is mounted on the manipulator for substrate rotation.The brushless motor with its speed controller allows to maintain a constant RPM even at variable load. The MCU housing is compatible with the 19" rack system.

The front panel’s height is 3 U (128.4mm) and the width is 20 HP (101.3mm). The installation depth is 170mm and requires an additional space of about 50mm at the back side for the connectors. The figure on the right shows the front panel of the manipulator control unit.

The speed of the substrate rotation is either set manually by the potentiometer on the front panel or by an analogue voltage input on the remote control connector (on backside). Operation of start, stop and direction of rotation is also either accomplished by front panel switches or by digital input signals (logical TTL or external relay switch).

Application

The use of the MCU is recommended for all our substrate manipulators,

e.g. SH 200-4G50.

The MCU can of course also be used for any other application where a

continuous rotation with precise speed control is required.