- Compact multifunctional table top annealing oven

- Applications:

- RTP / RTA processing

- ohmic contact formation

- device testing

Fast ramping up to 600°C

Interactive programmable controller for temperature and pressure profiles

Heater plate size 15 mm x 30 mm

Six contacts for electrical in-situ measurements; analog output for pressure and temperature measurements

Vacuum, inert gas or forming gas operation

Dry running diaphragm pump optionally available

Introduction

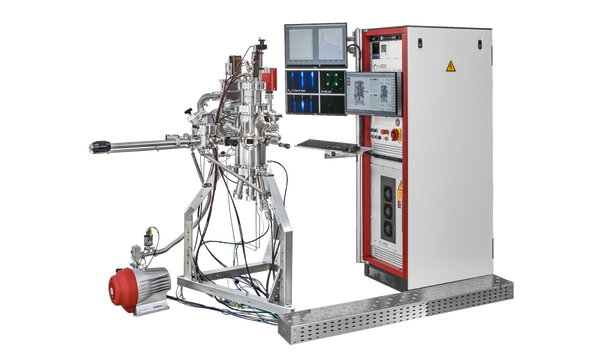

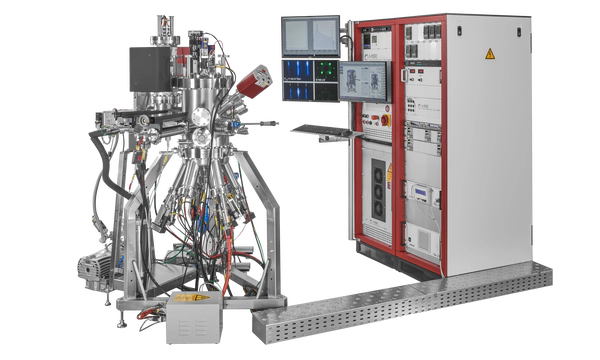

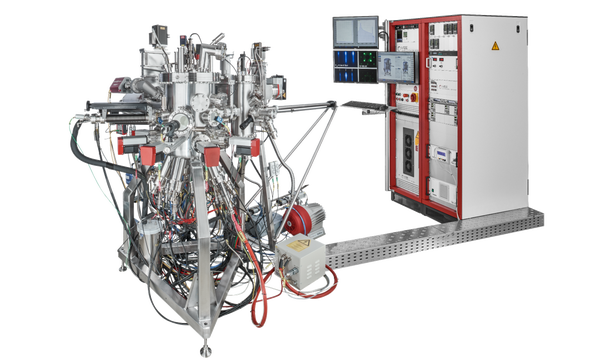

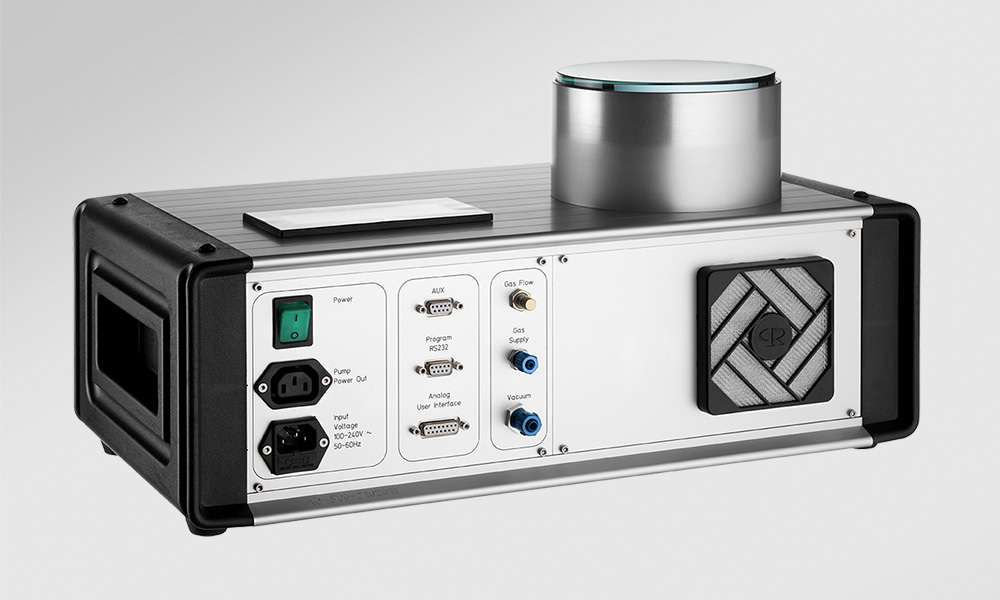

The Compact Rapid Thermal Annealing System AO 600 is a complete, free

standing table top annealing system with small footprint. The oven

itself as well as all power supply and control hardware are housed in a

compact 3U box.

A dry running diaphragm pump that provides the necessary vacuum (down to

less than 5 mbar) is sold along with the oven on request.

The AO 600 is capable of heating small sized samples under precisely

controlled conditions from room temperature up to 600°C.

Typical applications of the AO 600 are thermal treatment processes such

as rapid thermal annealing (RTA) of semiconductor samples, forming of

electrical contacts and investigation of intermixing and temperature

stability effects in semiconductors.

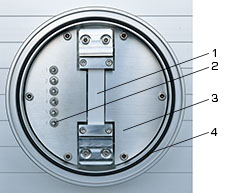

(1) heater plate 15 mm x 30 mm

(2) six contact pins for substrate measurement

(3) glass plate

(4) o-ring seal

The built-in micro controller sets power and thus temperature of the heater plate, as well as it switches the gas supply and the external vacuum pump. All functions needed for operation of the oven are visualized and can be set on the touch screen display on top of the box.

In order to achieve clean and reproducible operation and to avoid sample contamination and oxidation during the heat treatment samples can be operated in inert gas (Ar, N 2 , etc.) or forming gas (H 2 /N 2 mixture) atmosphere (flush-mode, 10…1000mbar) or in vacuum (pumping-mode <5mbar).

Sample load and removal can easily be done by removing the glass pane on top of the oven. This large pane also gives easy optical access to the recipient. In this way it is possible to use a microscope for observing the sample during the annealing process.

The direct current driven heater plate is made of thin film Al 2 O 3 . Temperature measurement is done by means of a PT 100 sensor, which is in direct contact with the heater. This design allows precise temperature control and a rapid heating up of the heater due to minimized thermal inertia, and provides a low thermal load to the recipient.

Application

Typical applications for the AO 600 Compact Rapid Thermal Annealing System are the following:

General RTP / RTA sample processing

Elecrical contact formation

Diffusion processes and indiffusion studies

Device testing under different temperature, gas and vacuum levels

Investigation of intermixing effects

Material alloying processes

Gas sensor characterization / development

Thermochromic material

Every application requires a specific sequence of pumping, venting,

flushing, ramping and holding steps, varied according to the

requirements of the particular process. The internal memory of the

integrated micro-controller allows the storage of 20 different user

programs, each comprising up to 30 free definable steps. Interactive

process control for each programm step is possible by 8 input and 4

output signals. Further analog 0…10 V signals allow process

logging of temperature and pressure measurements.

The recipient of the AO 600 is equipped with additional electrical feedthroughs (max. current 1 A, max. voltage 50 V) which can be applied for in-situ resistance monitoring during the annealing process or I-V-characterization of the sample using the integrated contact pins.

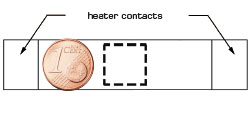

A sketch of the hot plate (width 15 mm) is shown on the right. The 1 Euro Cent coin illustrates the proportions.

Contact area, resistive heating via metal film and temperature measurement PT 100 sensor are located on the backside.

The dashed line marks the uniform temperature area (12x12 mm 2 ).

References

There are several publications about the Annealing Oven AO 600. Please have a look at section References / List of Publications.

Technical Data

| Temperature range | RT up to 600°C |

| Temperature stability | ±1°K (absolute) |

| Heating up speed | up to 50°K/s (vacuum anneal)* |

| Cooling down speed | up to 12°K/s (gas flow anneal)* |

| Useful substrate dimensions | 12 mm x 12 mm |

| Min. operating pressure | < 5 mbar |

| Max. inlet gas pressure | 1.2 bar abs (inert gas, forming gas) |

| Power supply | 230 V / 50 Hz |

* depends on sample temperature

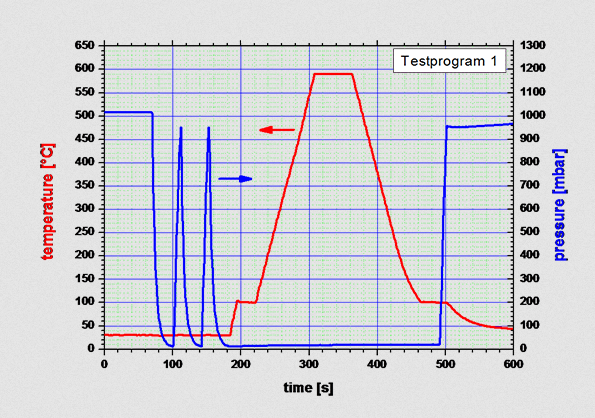

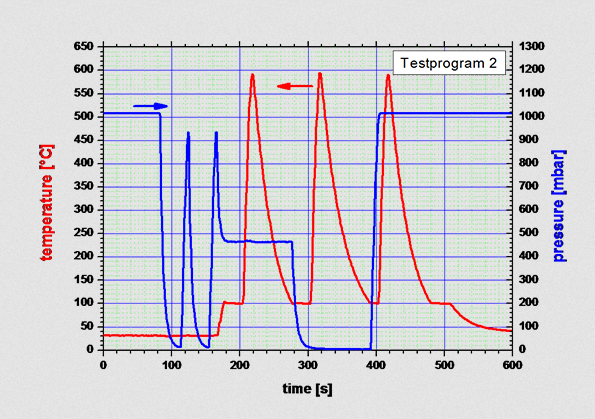

The following diagrams are examples for practicable AO 600 sequences. The red diagrams show progammable temperature ramping and feasible rapid temperature changes while the blue diagrams indicate possible pressure changes of inert gas or forming gas.

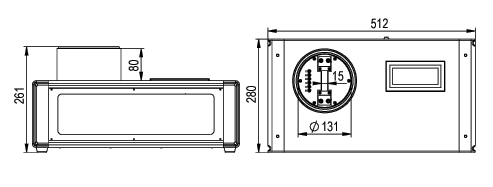

Dimensions