- Thermal sublimation of atomic carbon

- Refractory metal tube filament filled with ultrapure carbon

- Only pyrolytic graphite and tantalum parts in hot area

- Water-cooled power feedthrough

- Cooling shroud and shutter optionally available

- Compatible with UHV analysis systems and MBE growth chambers

Introduction

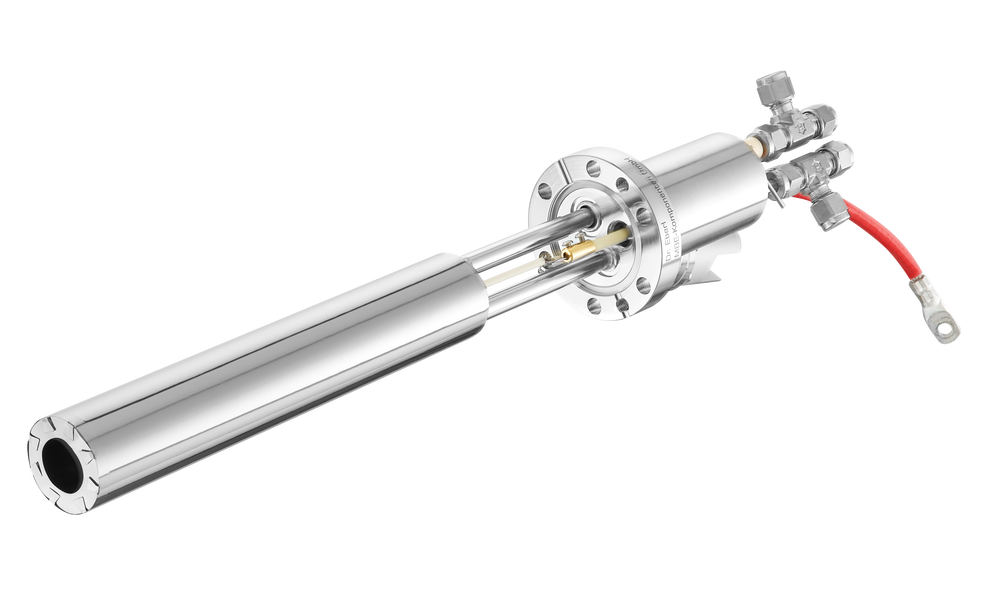

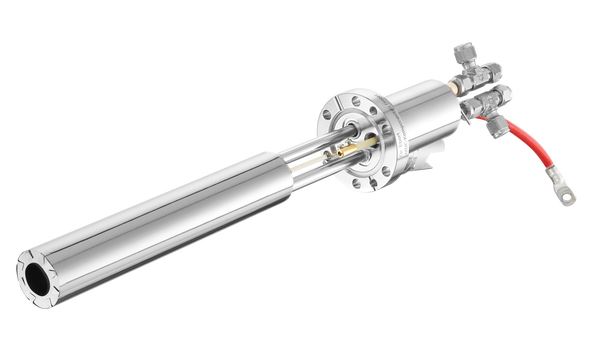

The Carbon Sublimation Source SUKO-A provides pure, highly reactive atomic carbon with a vast majority of C1 instead of the large percentage of C2 and C3 clusters (~75%) that are naturally released during the sublimation of graphite.

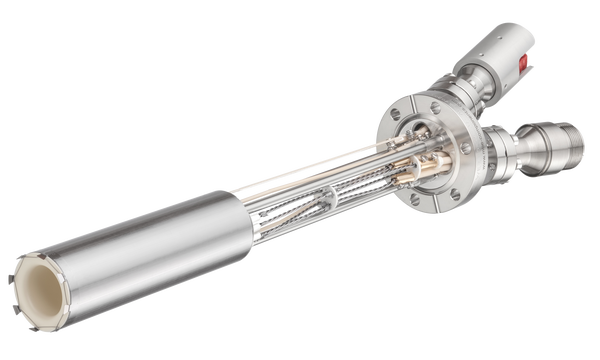

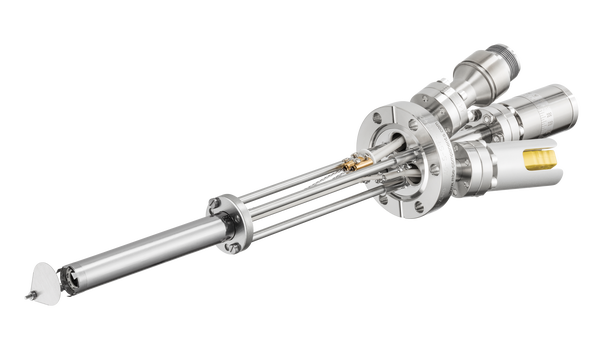

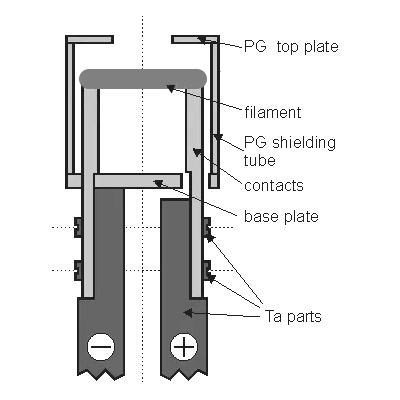

The extraordinary filament consists of a refractory metal tube, filled with carbon. At temperatures above 1800°C, carbon diffuses through the tube and sublimates from its outer surface. The tube itself acts like a filter, letting only atomic carbon pass.

The University of Jena patented this technique in collaboration with Dr. Eberl MBE-Komponenten GmbH. Several publications dealing with the Atomic Carbon Sublimation Source SUKO-A have already been published. They are listed in section References / List of Publications .

Disturbing outgassing of undesirable material is effectively prevented by the proven design of the SUKO-A, using solely pyrolytic graphite around the filament.

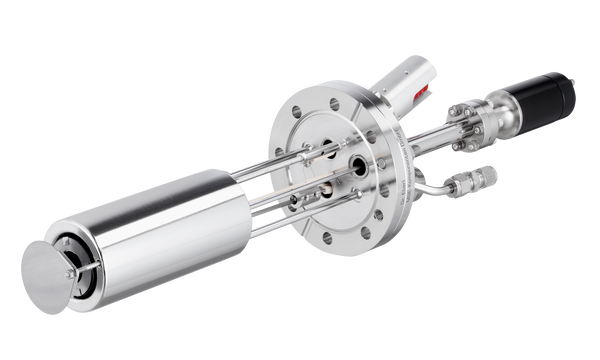

The power feedthrough is water-cooled and process safe without any water or vacuum welding seam.

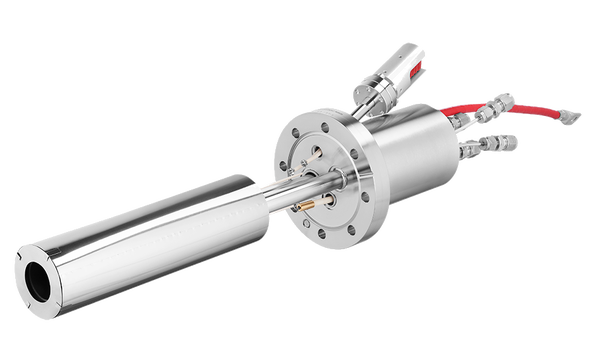

Direct heating of the filament by a DC power supply enables reliable and easy handling.

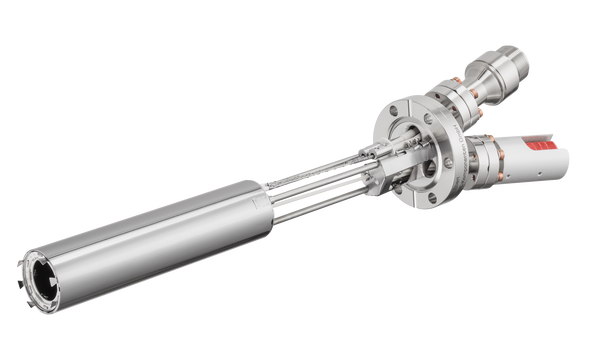

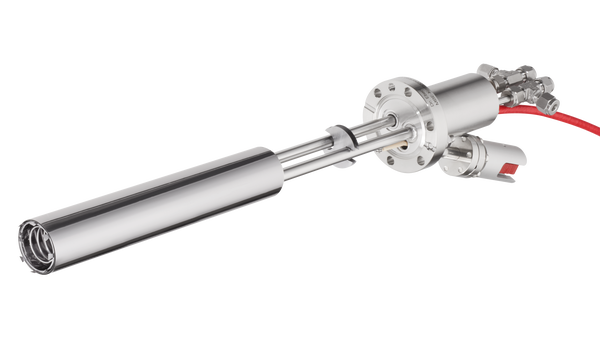

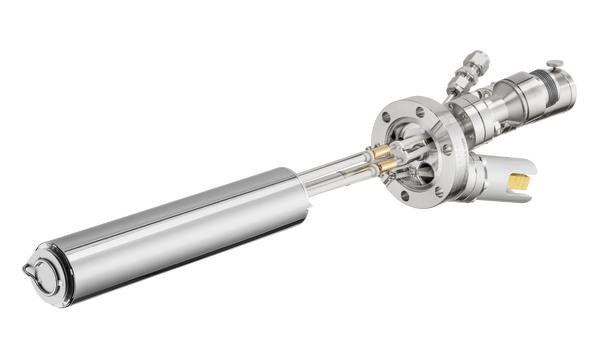

Appearance and dimensions of the SUKO-A are similar to the well-proven standard Carbon Sublimation Source SUKO . In fact, with a few spare parts users can convert every existing SUKO source into a SUKO-A, and vice versa, in their own laboratory.

The SUKO-A is available in two sizes, on either DN40CF (O.D. 2.75") or DN63CF (O.D. 4.5") flange. It can be easily mounted into common UHV analysis systems or MBE growth chambers.

Cooling shroud and shutter, highly recommended for the majority of applications, are optionally available.

The following table shows the required electrical power and typical flux rates at 100 mm working distance of the currently available SUKO-A models.

| Source type | Mounting flange | Electrical power | Carbon flux |

| SUKO-A 40 | DN40CF (O.D. 2.75") | 500 W | 0.1 nm/min |

| SUKO-A 63 | DN63CF (O.D. 4.5") | 1000 W | 0.5 nm/min |

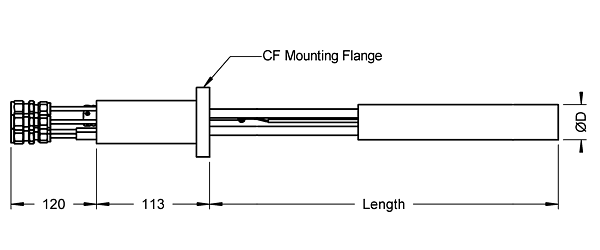

| Mounting flange | DN40CF (O.D. 2.75") or DN63CF (O.D. 4.5") |

| Dimensions in vacuum | L=250-400 mm, D=36 or D=55 mm |

| Filament type | refractory metal tube filled with carbon |

| Filament shielding | filament completely shielded with PG parts |

| Thermocouple | W5%Re/W26%Re (type C) |

| Bakeout temperature | max. 250°C |

| Operation temperature | max. filament temperature 2300°C |

| Electrical contacts | water-cooled (4x Swagelok fitting connection O.D. 6 mm); water flow min. 30 l/h |

| Cooling | separate water (or LN2 ) cooling shroud |

| Options | integrated rotary shutter ( S ) |

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Shutter* | UHV dimensions*** [mm] | max. electrical [W]/[A] | Growth rate** | Power supply product code | |

|---|---|---|---|---|---|---|---|

| [mm] / [mm] | [W] / [A] | [nm/min] | Product code | ||||

| SUKO-A | 40 - | LxxxD36 | 500 / 75 | 0.1 | PS 20-76 | ||

| SUKO-A | 63 - | S - | LxxxD55 | 1000 / 110 | 0.5 | PS 20-120 |

* rotary shutter possible on same flange ** maximum growth rate at 100mm distance *** specify UHV length L with order

Product code: e.g. SUKO-A 63-S-L300D55 is an atomic carbon sublimation source on DN63 CF-flange with shutter, in-vacuum length 300mm and diameter 55mm.