- Compatible with standard MBE systems, e.g. from Varian, EPI, Veeco, VG, or Riber

- Crucible capacities 40-1700 cm³

- Precise run-to-run flux reproducibility

- Customized beam shaping crucible inserts available

- Excellent reliability and long lifetime

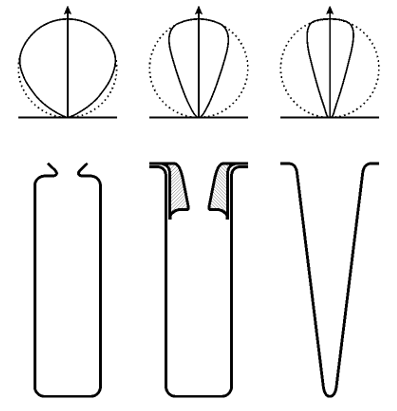

- Hot lip, cold lip and dual filament designs

- Optional integrated cooling shroud

- ISO-K cells available for HV applications Datasheet

Introduction

Production Effusion Cells PEZ are designed to meet the particular

requirements of production MBE systems with higher throughput.

Their wide operating temperature range of 200-1400°C allows evaporation

or sublimation of a large number of elements and compounds, including

standard III-V and II-VI MBE materials such as Al, Ga, In, As, or Zn.

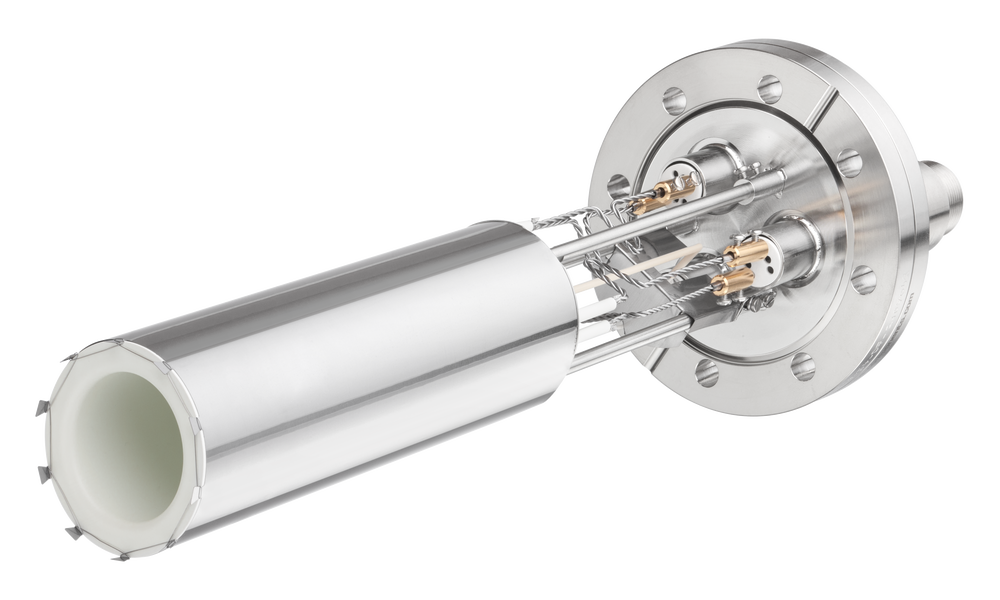

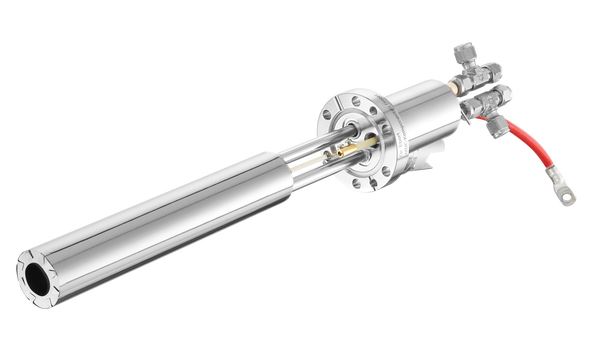

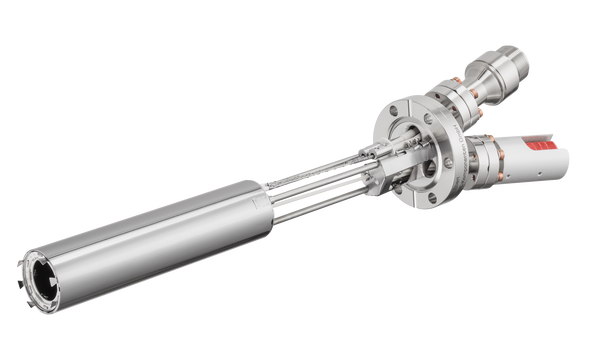

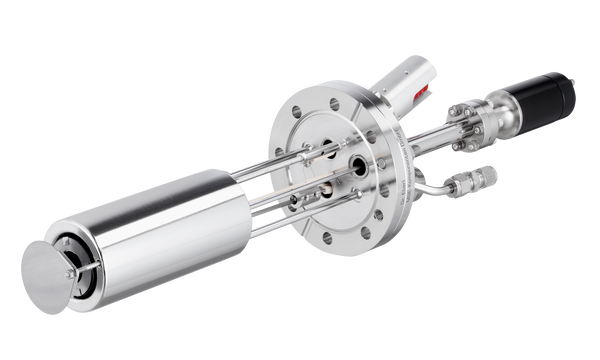

Besides standard filaments SF , hot-lip HL , cold lip CL and dual filament DF configurations are available, meeting the differing requirements of the evaporation materials. The picture on the right-hand side details a PEZ with dual filament.

The standard crucible material for the PEZ is PBN. PEZ cells are either equipped with conical or cylindrical crucibles, depending on the MBE chamber design, and offer precice flux reproducibility and excellent thickness uniformity.

Further improvements of source material utilization and flux stability can be achieved by using of a customized beam shaping insert in combination with a large capacity crucible. Crucible inserts not only reduce the effect of fill level-related flux shift, but also act as a thermal buffer virtually eliminating shutter transients (see [Application](#application pez) for more details).

Similar to our standard effusion cells, the crucible is heated by a wire filament supported by PBN rings. The advantages of this heating assembly are described on page WEZ.

The consequent use of power and TC feedthroughs on separate DN16 CF flanges allows easy servicing.

For large scale production systems crucible capacities up to 1700 cm³ (and more ) are available.

The PEZ design offers enough flexibility to adapt to the particular requirements of UHV deposition applications with high throughput such as commercial fabrication of III-V semiconductor devices or thin film solar cell production.

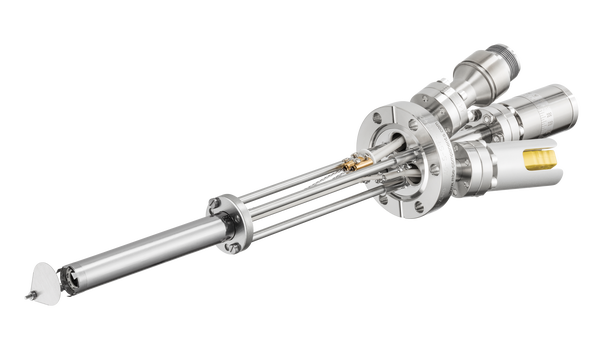

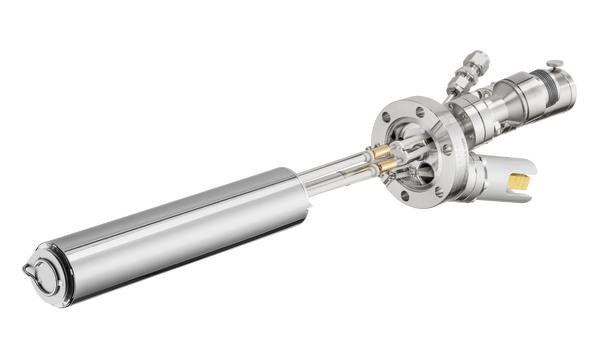

The right-hand picture shows the PEZ 150-700-124-DF, a large production effusion cell with conical 700 cm³ crucible and dual filament. This cell is typically used for evaporation of III metals simultaneous on several semiconductor samples in III-V MBE production systems.

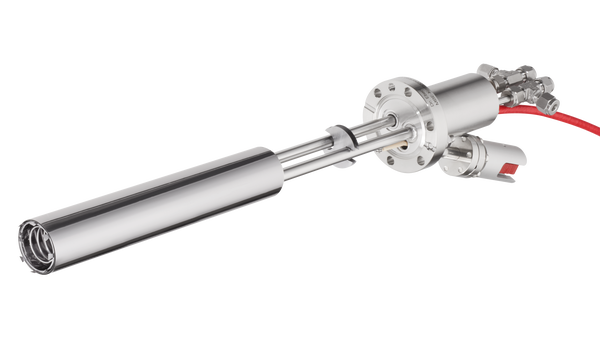

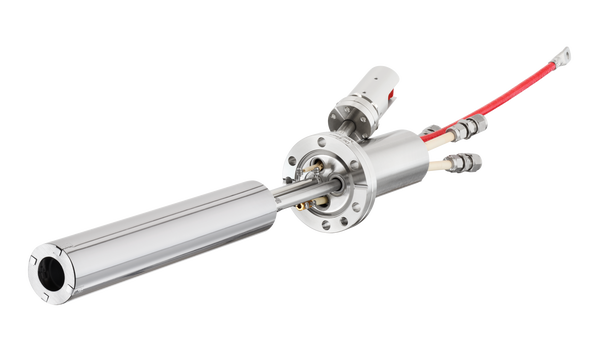

ISO-K cells for HV applications are also available. The picture on the right shows two examples on 160K flanges, a PEZ 160K-500-90-(S) with 500 cm3 nominal crucible capacity and a PEZ 160K-160-98-K with 160 cm3 nominal crucible capacity.

Application

The PEZ is recommended for elements and compounds evaporated or

sublimated at temperatures in the range 200-1400°C, e.g. Al, Ga, In, As,

Zn, etc.

Compared with our standard effusion cell WEZ, the PEZ is distinguished

by a more robust cell design and the consequent optimization of many

details leading to a further improvement of stability and

reproducibility, as well as excellent reliability and easy servicing.

The PEZ is thus ideally suited for production MBE systems.

For MBE applications that require a wide-area homogeneous growth, the use of conical crucibles (e.g. in cell type PEZ 63-40-51-K) is recommended. A compact hot lip filament improves the critical power management in the upper crucible zone by reducing the heater wire temperature, equivalent to less chemical corrosion. In addition, the more robust radiation shielding and cell heater housing as well as flange protection tubes reduce the risk of chemical corrosion and electrical short-circuits caused by liquid metals (gallium).

Especially designed for Ga or In deposition in III-V MBE systems, the

PEZ with large cylindrical crucibles (130 cm 3

or larger) can be equipped with a customized crucible

insert.

The use of a very large crucible with a beam shaping insert combines the

advantages of conical and cylindrical crucibles:

The crucible insert provides conical beam shaping, resulting in minimized waste of material and excellent uniformity.

Conical crucibles show the effect of fill level-related flux shift, due to the continuous changing of the evaporation material surface. This effect is widely reduced in PEZ cells with insert, because the apparent surface remains constant during a growth campaign.

Shutter transients are a common problem for layer growth when using standard crucibles with wide orifice. The influence on the thermal stability of the molten material caused by shutter action is virtually eliminated by the crucible insert’s function as a thermal buffer in combination with dual filament heating.

Dual filament heating allows keeping the conical insert at higher temperatures which avoid material condensation. It is a mandatory feature when using inserts.

Large Capacity Ga/In PEZ cells feature a material efficiency up to 25%

better than SUMOTM type cells.

A PEZ with 130 cm³ crucible and insert is capable of holding a maximum

Ga load of 500 g, depending on the actual mounting angle. With 1500 cm³

crucible the maximum Ga load is even increased to 5 kg.

Technical Data

| Filament type | Ta wire heating filament: standard ( SF ), hot lip ( HL ), cold lip ( CL ), dual ( DF ) |

| Thermocouple | W5%Re/W26%Re (type C) (type K on request) |

| Operating temperature | 200-1400°C (recommended 700-1300°C) |

| Outgassing temperature | 1500°C |

| Bakeout temperature | 250°C |

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 40-1700 cm³ (larger capacity on request); crucible material: PBN |

| Options | integrated water cooling shroud ( K ) |

Crucibles

Standard crucible material for the PEZ is PBN. Other crucible materials are available upon request.

Depending on evaporation material and chamber geometry, PEZ cells can be

equipped either with conical (e.g. 40 cm³, 60 cm³, 1700 cm³) or

cylindrical crucibles. Unless not explicity refused, PEZ cells with

cylindrical crucible are as standard delivered with an additional

customized beam shaping crucible insert.

For detailed information see page

Crucibles .

The second number of the product code is the nominal crucible capacity [in cm³], the third number indicates the lip diameter of the crucible. Please specify crucible material, if not PBN.

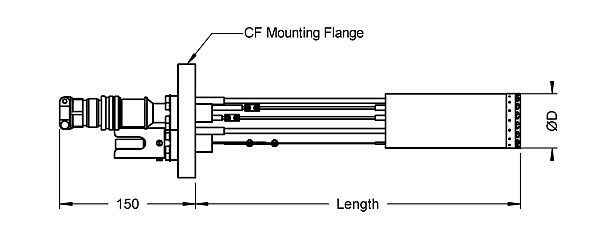

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Filament type | Thermocouple | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | Type | Type | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||

| PEZ | 63 - | 85 - | 41 - | K - | SF ¹ - | C - | P - | LxxxD62 | 565/ 11 | PS 40-19 | CRU 85-41 | ||

| PEZ | 63 - | 25 - | 51 - | K - | SF¹ - | C - | P - | LxxxD62 | 555 / 17 | PS 40-19 | CRU 25-51 | ||

| PEZ | 63 - | 40 - | 51 - | K - | SF ¹ - | C - | P - | LxxxD62 | 555 / 17 | PS 40-19 | CRU 40-51 | ||

| PEZ | 63 - | 60 - | 54 - | S- | SF ¹ - | C - | P - | LxxxD55 | 775 / 15 | PS 80-19 | CRU 60-54 | ||

| PEZ | 63 - | 80 - | 54 - | S- | SF ¹ - | C - | P - | LxxxD55 | 835 / 16 | PS 80-19 | CRU 80-54 | ||

| PEZ | 63 - | 125 - | 54 - | S- | SF ¹ - | C - | P - | LxxxD55 | 1140 / 14 | PS 100-15 | CRU 125-54 | ||

| PEZ | 63 - | 130 - | 54 - | S- | SF ¹ - | C - | P - | LxxxD55 | 1140 / 14 | PS 80-19 | CRU 130-54 | ||

| PEZ | 63 - | 200 - | 58 - | SF ¹ - | C - | P - | LxxxD58 | 1360/ 16 | PS 80-19 | CRU 200-58 | |||

| PEZ | 63 - | 150 - | 60 - | K - | SF ¹ - | C - | P - | LxxxD62 | 1000 / 14 | PS 80-19 | CRU 150-60 | ||

| PEZ | 100 - | 200 - | 84 - | K - | SF ¹ - | C - | P - | LxxxD84 | 1800 / 14 | PS 120-25 | CRU 200-84 | ||

| PEZ | 100 - | 420 - | 84 - | K - | SF ¹ - | C - | P - | LxxxD84 | 1800 / 14 | PS 120-25 | CRU 420-84 | ||

| PEZ | 150 - | 700 - | 124 - | DF - | C - | P - | LxxxD125 | 2300 / 27 | PS 100-33 | CRU 700-124 | |||

| PEZ | 150 - | 1500 - | 124 - | DF - | C - | P - | LxxxD125 | 2500 / 30 | PS 100-33 | CRU 1500-124 | |||

| PEZ | 200 - | 1700 - | 164 - | K - | DF - | C - | P - | LxxxD180 | 3000 / 35 | PS 120-50 | CRU 1700-164 |

* rotary shutter possible on same flange Note: max. Power/Current and Power supply are dependent on filament operating mode (SF, Cl, TF, HL or DF) ** PBN standard, other materials on request ¹ alternatively CL, TF, HL or DF *** specify UHV length L with order

Larger sizes for industry applications are available, too. Please have a

look at Industrial Sources .

*

Product code:

*

e.g. **PEZ 63-85-41-K-CL-C-P-L326D62

** is a production effusion cell on DN63 CF-flange for a 85cm³ crucible, with integrated water cooling shroud, cold lip filament, type C thermocouple, PBN crucible, in-vacuum length 326mm and diameter 62mm.