- Oxygen resistance option available for most wire heater effusion cells

- Applicable in oxide MBE systems with chamber pressures up to several mbar

- Nickel alloy wire heaters up to 1000°C

- Noble metal alloy wire heaters up to 1200°C

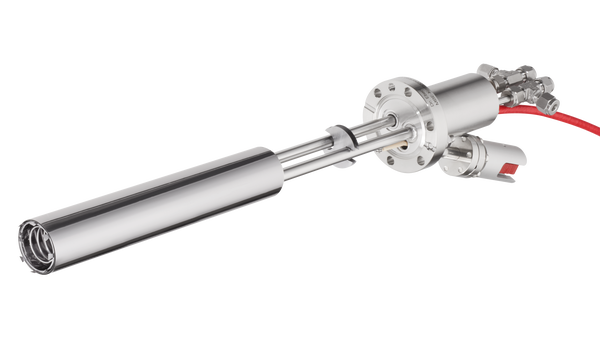

- Ultimate oxygen resistance by use of platinum shielding

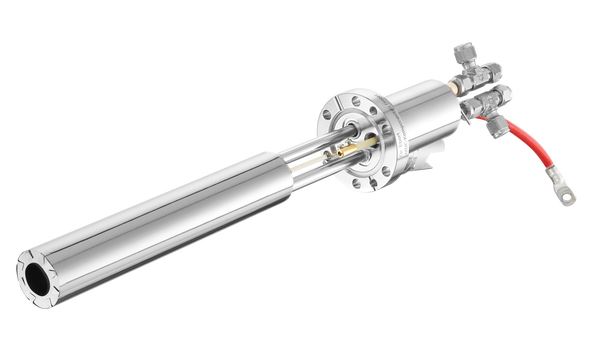

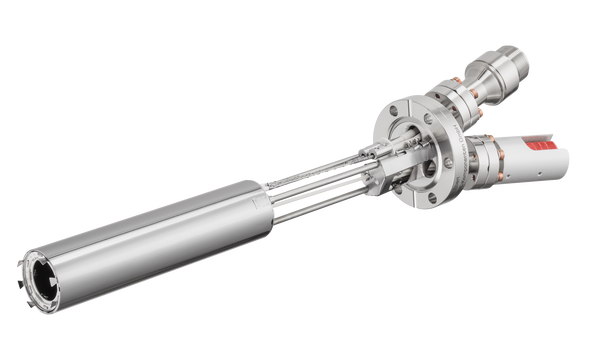

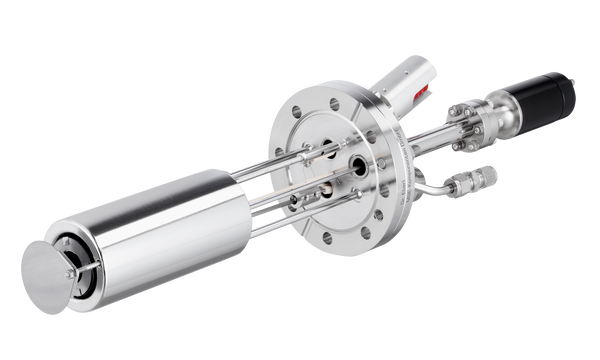

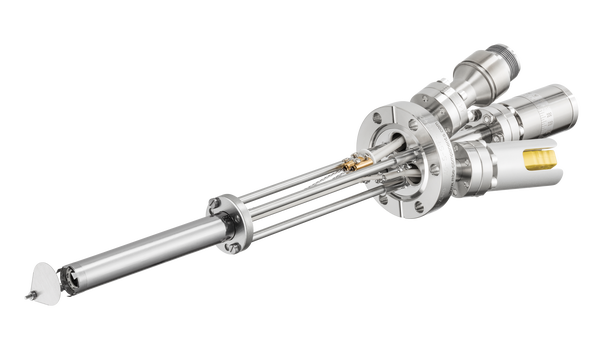

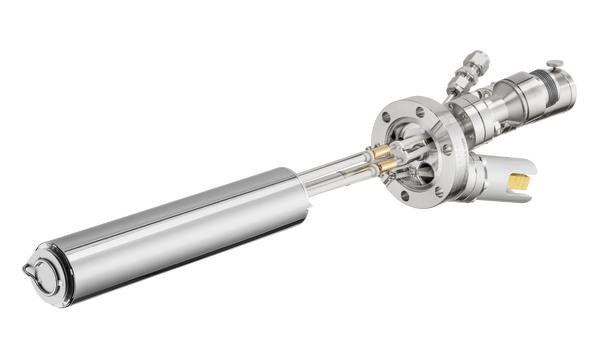

- Optional on-flange integrated cooling shroud and shutter

Introduction

Oxygen Resistant Effusion Cells OREZ meet the requirements of oxide MBE and other vaccum applications with high oxygen background pressure. OREZ cells are typically employed in systems with a working pressure from 10 -4 to several mbar and can be used up to 1200°C, e.g. for growth of ZnO layers.

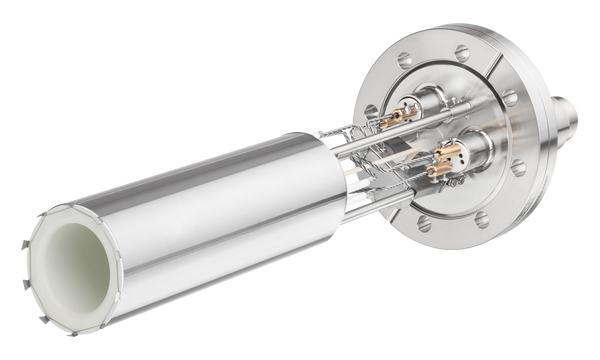

Consequent use of selected noble metal and nickel based construction

materials render the best possible improvement of common UHV effusion

cell models with respect to resistance against oxygen-rich

environments.

Special Ni alloy heater wire and shielding parts allow operation in UHV

and oxygen-containing atmosphere up to a cell temperature of 1000°C.

Operating temperatures of up to 1200°C are attainable by using noble

metal alloys for both heater and shieldings.

Since OREZ cells are essentially modifications of standard wire heater

effusion cells, almost the same range of flange and crucible sizes is

available as for

WEZ and

NTEZ effusion cells.

The same also applies to the number of available options. OREZ cells are

offered with the full range of filament configurations. Integrated

cooling and shutter are possible as required. The OREZ can thus

be adapted to almost every vacuum system.

In view of the wide range of applications and evaporants, there is no standard crucible material for the OREZ. The most commonly used materials are PBN, Al2O3 , BeO, and iridium. The maximum admissible temperature for PBN however depends on the oxygen pressure level, due to the formation of boron oxide.

Application

A steadily increasing number of applications requires robust, reactive

gas resistant equipment for material deposition, often employed in

combined UHV and reactive gas process steps carried out in one vacuum

system.

OREZ cells are therefore designed to operate in a pressure range from

UHV up to nearly atmospheric pressure. Best performance is achieved in a

pressure range from 10-6 to 10-3 mbar.

Typical applications are the formation of oxide layers by surface oxidation, growth of oxide films by evaporation of metals in oxygen atmosphere, and direct evaporation of oxides. Surface oxide layers and thin films are widely used as insulator materials, e.g. in microelectronic devices. Thick oxide films are often used in sensors and optical devices, due to the multifaceted optical, magnetic, electrical and semiconductive properties of oxides.

Note : For chamber pressures below 10-6 mbar we recommend using standard UHV effusion cells ( WEZ , NTEZ , etc.). For higher pressures above 10 -3 mbar it should be taken into account that due to the very short free path length of the evaporated molecules one leaves the molecular beam regime. In both cases please inquire for more advice.

Technical Data

| Filament type | Ni alloy (Tmax = 1000°C) or noble metal alloy (T

max = 1200°C) wire heating filament: standard ( SF ), hot lip ( HL ), cold lip ( CL ), dual ( DF ) |

| Thermocouple | NiCr/NiAl (type K) |

| Operating temperature | 200-1200°C (depending on filament material and operation conditions) |

| Outgassing temperature | 1000 / 1200°C (depending on filament material) |

| Bakeout temperature | 250°C |

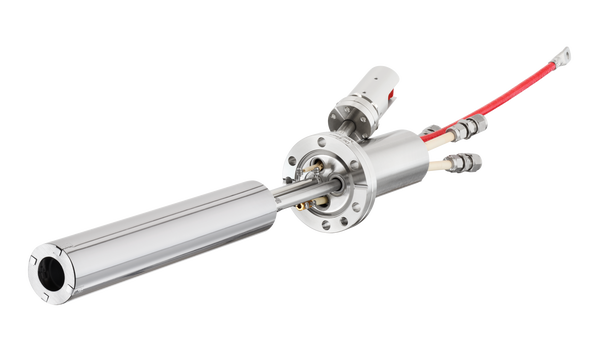

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 10-125 cm³; PBN, Al2O3 , BeO crucibles (other materials on request) |

| Options | integrated water cooling ( K ), integrated rotary shutter ( S ) |

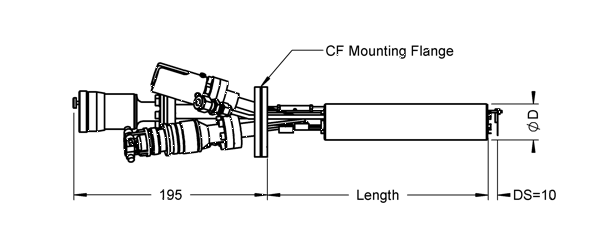

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Filament material | Shielding material | Filament type | Thermocouple | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | Type | Type | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||||

| OREZ | 40 - | 10 - | 22 - | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD34 | 120 / 7 | PS 30-10 | CRU 10-22 | ||

| OREZ | 40 - | 10 - | 22 - | K | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD36 | 120 / 7 | PS 30-10 | CRU 10-22 | |

| OREZ | 40 - | 35 - | 34 - | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD34 | 180 / 9 | PS 30-10 | CRU 35-34 | ||

| OREZ | 40 - | 35 - | 37 - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD37 | 200 / 10 | PS 30-10 | CRU 35-37 | |||

| OREZ | 40 - | 60 - | 37 - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD38 | 240 / 10 | PS 30-10 | CRU 60-37 | |||

| OREZ | 63 - | 35 - | 34 - | K | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD58 | 180 / 9 | PS 30-10 | CRU 35-34 | |

| OREZ | 63 - | 35 - | 37 - | K | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD54 | 200 / 10 | PS 30-10 | CRU 35-37 | |

| OREZ | 63 - | 60 - | 37 - | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD38 | 240 / 10 | PS 30-10 | CRU 60-37 | ||

| OREZ | 63 - | 60 - | 37 - | K | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD58 | 240 / 10 | PS 30-10 | CRU 60-37 | |

| OREZ | 63 - | 60 - | 54 - | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD55 | 300 / 10 | PS 40-19 | CRU 60-54 | ||

| OREZ | 63 - | 125 - | 54 - | S - | Ni¹ / | Ni² - | SF³ - | K - | P - | LxxxD55 | 300 / 10 | PS 40-19 | CRU 125-54 |

* rotary shutter possible on same flange ¹ Pt alloy wire filament on request ** no standard, inquire for your particular solution ² Pt foil shielding on request *** specify UHV length L with order ³ alternatively CL, HL or DF

Product code: e.g. OREZ 40-10-22-S-Pt/Ni-HL-K-B-L287D34 is an oxygen resistant effusion cell on DN40 CF-flange for a 10cm³ crucible (lip Ø 22mm), integrated rotary shutter, Pt foil shielding, Ni alloy wire hot lip filament, type K thermocouple, BeO crucible, in-vacuum length 287mm and diameter 34mm.