- Patented Thermal Conduction Cooling (TCC)

- Ideal for evaporation of sensitive organic materials in UHV and OLED applications

- Temperature range 15-300°C

- Fast and precise temperature control < ±0.02K with excellent temperature stability

- Crucibles capacities 2 cm³, 10 cm³ and 35 cm³

- Full UHV and MBE compatibility

- ISO-K cells available for HV applications Datasheet

Introduction

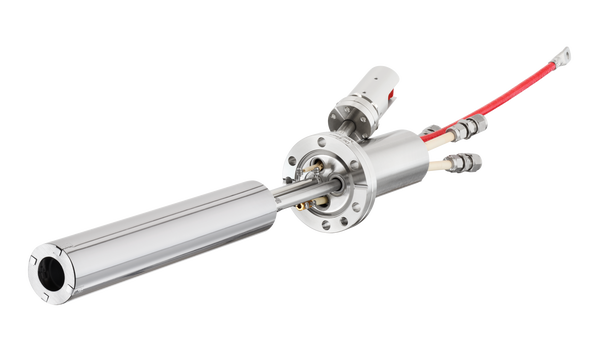

The Organic Material Effusion Cell OME is specially designed for the

evaporation or sublimation of high vapor pressure materials, notably

sensitive organic substances, at operating temperatures up to 300°C.

It can likewise be used for other elements and compounds typically

evaporated at very low temperatures, e.g. alkali metals.

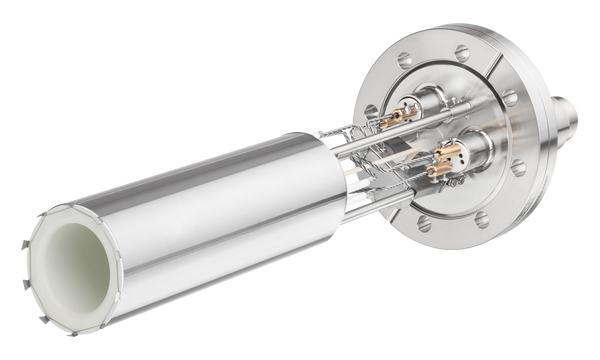

Due to Thermal Conduction Cooling (TCC) with encapsulated heater unit, a

patented design by MBE-Komponenten, the OME offers drastically improved

operation properties below the lowest temperature limit of common

Knudsen-type effusion cells.

Due to the T4 -dependency of emitted radiation power

according to the Stefan-Boltzmann law, conventional effusion cells with

Thermal Radiation Cooling (TRC) show a poor cooling efficiency at low

operation temperatures. This results in a low cell cooling rate that

renders precise temperature control below 150°C very difficult.

By contrast, the OME uses the linearity of the heat transfer between a

heated reservoir and a cooled heat sink to obtain a high cooling rate

even at very low operating temperatures. Rapid cooling down, low thermal

time constants and a stable temperature control are thus achieved.

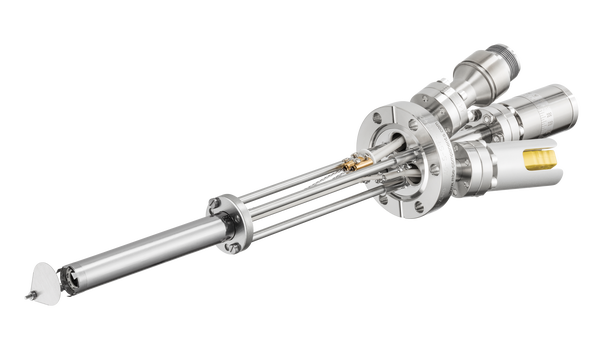

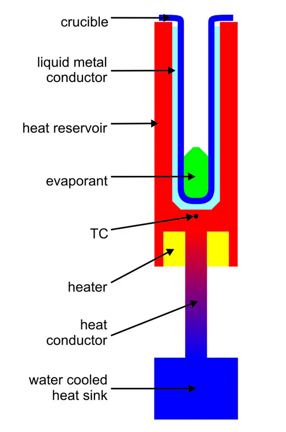

The novel TCC concept involves a liquid metal used as a thermal

conductor that provides a direct thermal connection between crucible and

heat reservoir, leaving no isolating voids. This excellent thermal

contact also guarantees a very uniform temperature distribution within

the crucible.

Precise temperature measurement is provided by a direct touching TC in the center of the heater area, near the crucible bottom. Accurate temperature indication is crucial for materials with steep vapor pressure curves.

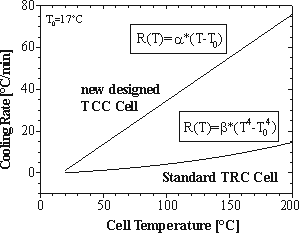

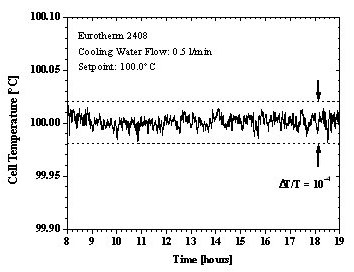

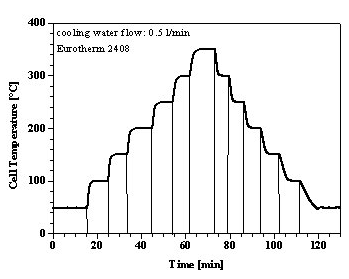

The data underlying the TCC curves in the following two diagrams were measured on a 2 cm³ OME 40-2-25 cell.

The first diagram on the right compares the cooling rates of the TCC

cell OME and a typical TRC effusion cell.

While the cooling rate of the TRC cell only slowly increases with cell

temperature in agreement with Stefan-Boltzmann law, the cooling rate of

the TCC cell increases linearly with temperature.

Despite its larger thermal mass the cooling rate of the OME is much higher at low temperatures and reaches 10°C/min even at 70°C cell temperature.

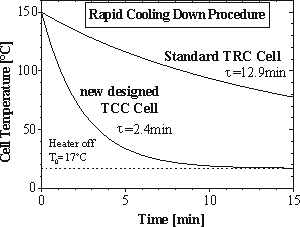

TCC cell OME and a TRC cell during a rapid cooling down procedure are compared in the second diagram on the right. It shows the resulting temperature decrease of both cells starting at the same cell temperature of 150°C.

After switching off the cell heaters the OME is cooling down about four times faster than a TRC cell comparable in size.

Application

The excellent low temperature properties of the TCC concept make the OME ideally suited for evaporation of temperature sensitive materials like organics, polymers and other high vapor pressure materials from room temperature up to 300°C. As an option, operation even below room temperature is possible by using a chilled cooling liquid.

In ordinary radiation heated (TRC) low temperature cells the evaporant may be locally overheated due to the direct view of the crucible onto the heater wires. In contrast, the crucible of the OME cell never reaches a temperature higher than the actual temperature of the surrounding heater body. Rapid heating up and cooling down rates avoid waste of expensive materials during idling times.

The diagramm on the left-hand side shows the excellent long term temperature stability of the OME. It displays a test run at setpoint 100°C with a constant cooling water flow of 0.5 l/min.

The measured stability over a period of 10 hours of operation with PID controller is better than ±0.02K.

The fast heating up and cooling down times of OME cells are shown on the second testing chart.

Remarkably, cells with TCC technique allow heating up and cooling down steps with absolutely no temperature overshoot. This is the qualification to prevent waste and potential destruction of the evaporants.

Technical Data

| Heating system | patented TCC technique with encapsulated Ta wire heater |

| Thermocouple | NiCr/NiAl (type K) |

| Operating temperature | 15°C-300°C (lowest temperature depending on cooling temperature) |

| Temperature stability | < ±0.02K (with standard PID controller) |

| Outgassing temperature | max. 350°C |

| Bakeout temperature | max. 250°C |

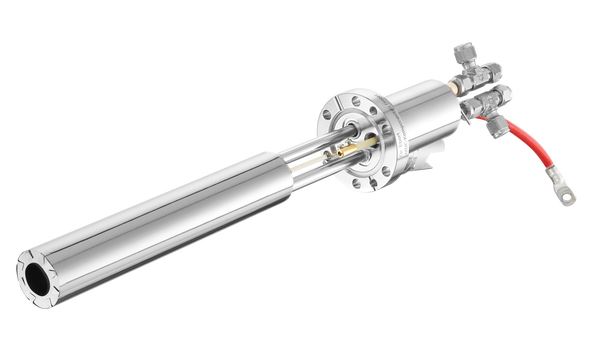

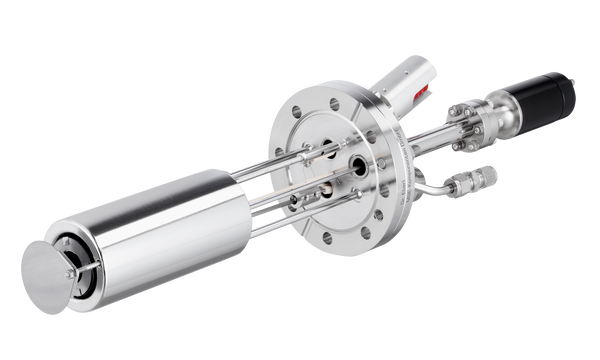

| Cooling | integrated water cooled heat sink; water flow > 0.5l/min required |

| Crucibles | 2-35 cm³ (conical shape on request); crucible material: quartz ( Q ) (others on request) |

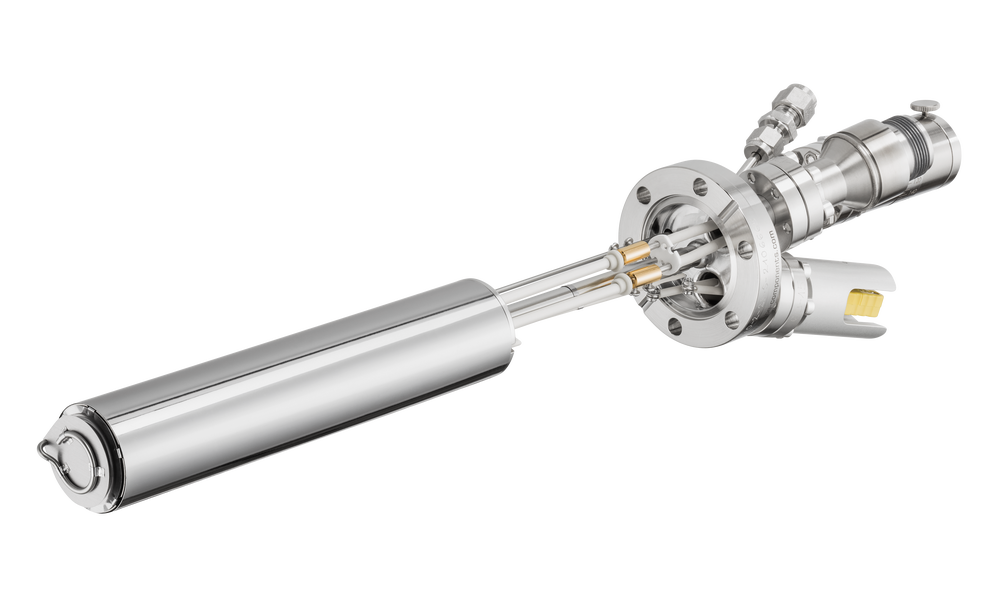

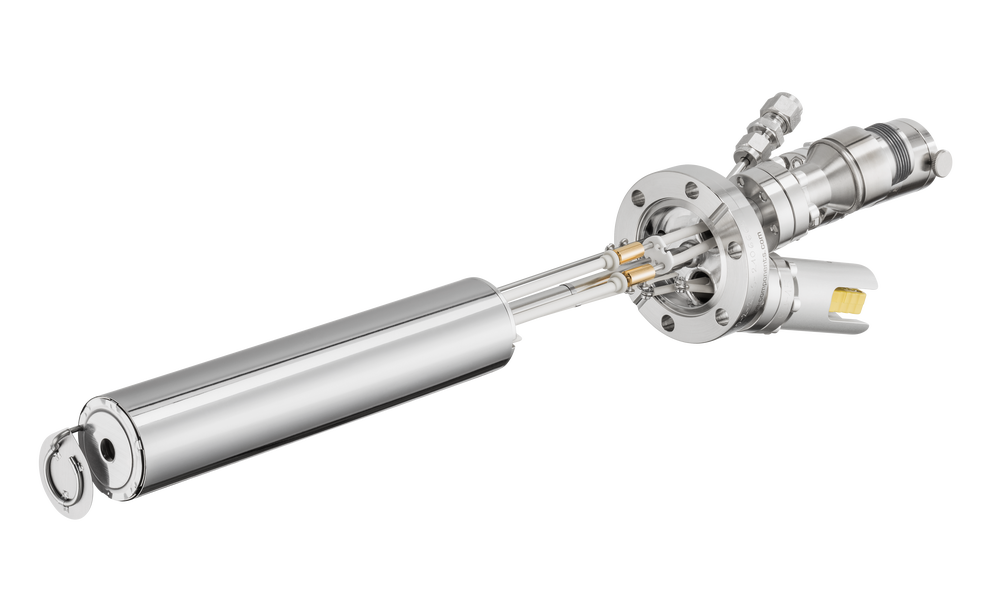

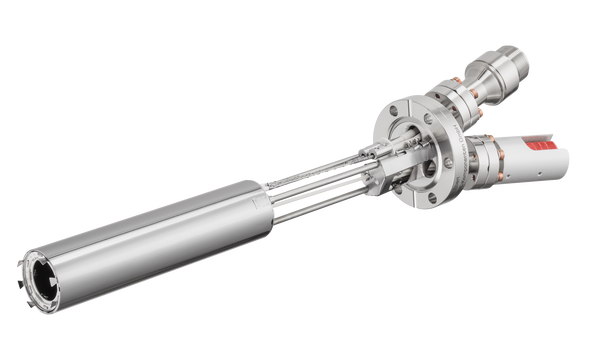

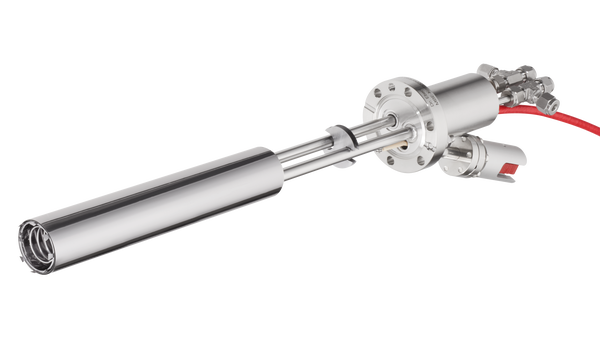

| Options | integrated rotary shutter ( S ); integrated tight

sealing shutter ( TS ), evacuation tube ( E ); aperture nozzle ( N ) |

Crucibles

The standard crucible material commonly used for organic evaporants is

quartz. For special requirements, e.g. evaporation of alkali metals,

other crucible materials like PBN or Al2O3 are

also available.

The best performance of the OME is achieved when the cell is mounted

upright in a rather vertical angle, though face-down operation is also

possible by using special insert crucibles. For information on crucibles

see Crucibles .

The second number of the product code is the nominal crucible capacity [in cm³], the third number indicates the lip diameter of the crucible. Please specify crucible material, if not quartz.

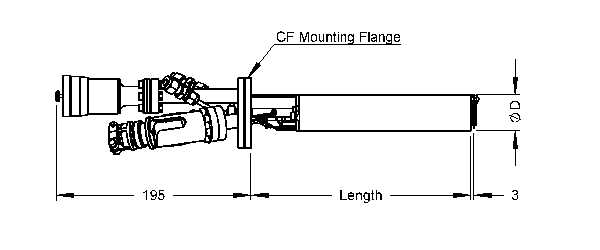

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Shutter* | Additional options | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | Option | [mm] / [mm] | [W] / [A] | Product code | Product code | |||||

| OME | 40 - | 2 - | 25 - | S, TS - | E¹ , N² - | Q - | LxxxD36 | 270 / 9 | PS 30-10 | CRU 2-25 | |

| OME | 40 - | 10 - | 35 - | S, TS - | E¹, N²- | Q - | LxxxD36 | 270 / 9 | PS 30-10 | CRU 10-35 | |

| OME | 63 - | 35 - | 37 - | S, TS - | E¹, N²- | Q - | LxxxD57 | 400 / 16 | PS 40-19 | CRU 35-37 |

* rotary or tight sealing shutter possible on same flange ¹ only available in combination with option TS ** Quartz standard, other materials on request ² specify nozzle diameter with order *** specify UHV length L with order

Product code: e.g. OME 40-10-35-TS-E-Q-L400D36 is an organic material effusion cell on DN40 CF-flange for a 10cm³ crucible (lip Ø 35mm), tight sealing shutter, evacuation tube, quartz crucible, in-vacuum length 400mm and diameter 36mm.