- Compatible with most MBE systems

- Various crucible sizes and materials; crucible capacities 1.5, 10, and 35 cm³

- Self-supporting tungsten wire heater

- Clean operation in UHV up to 1900°C

- High reliability and long lifetime

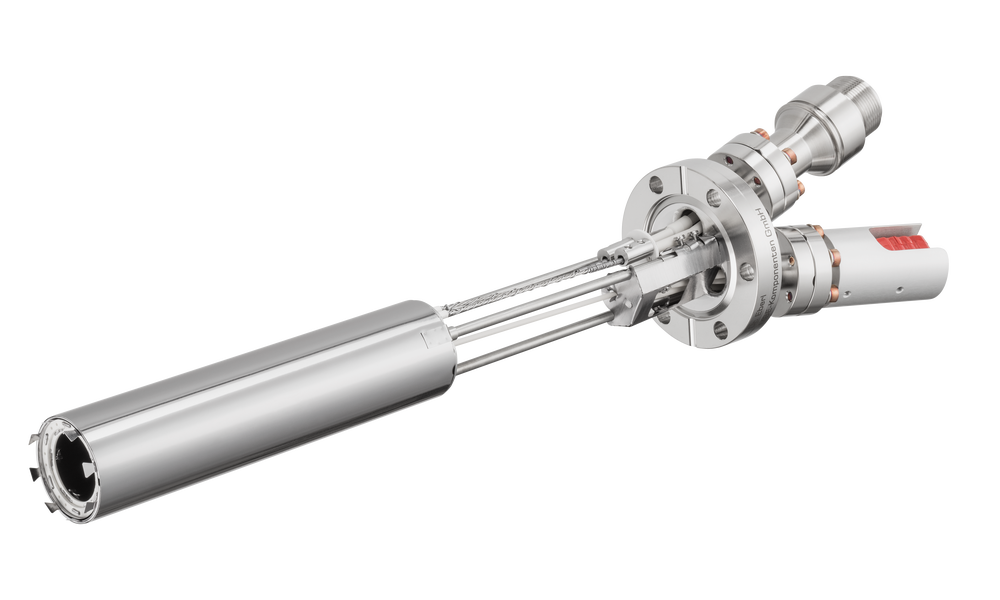

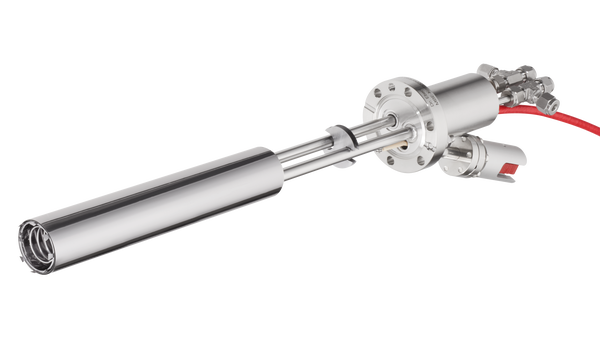

- Cell option with integrated cooling shroud and shutter

Datasheet

Introduction

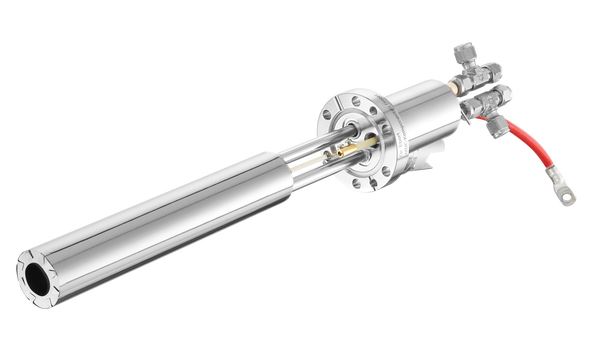

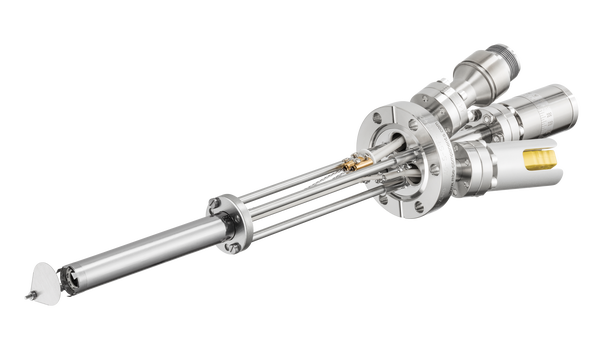

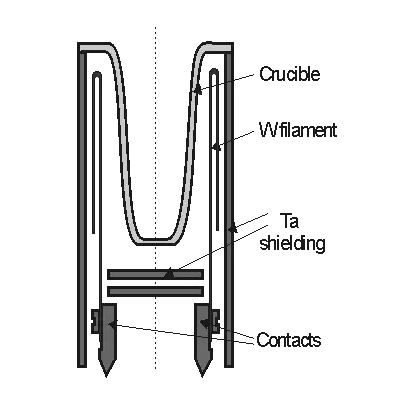

The High Temperature Effusion Cell HTEZ is designed for clean UHV

operation up to 1900°C. This is accomplished by a self-supporting

tungsten filament, whose schematic drawing is pictured on the right,

showing the main parts of the HTEZ heating system.

Equipped with a free-standing filament of thick tungsten wire, the top

model HTEZ-W is capable of reaching even 2000°C.

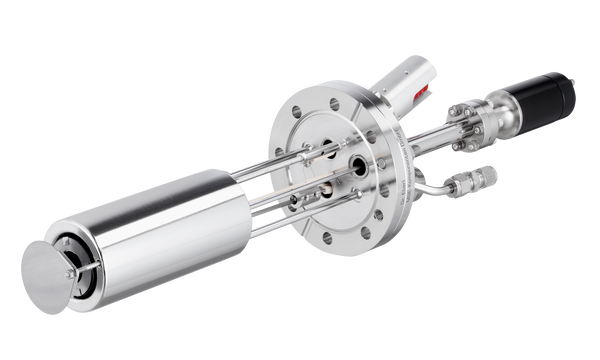

In contrast to the HTS sources, HTEZ cells predominantly heat the crucible from the side. The deep crucible design allows operation in angled port positions, combining large capacity with high temperature operation.

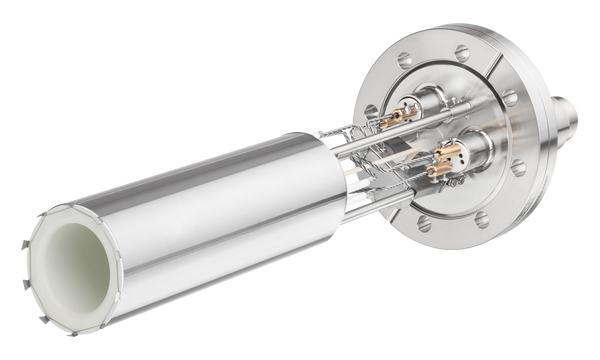

Like in the standard

WEZ heating system, only selected refractory

metals are used in the hot zone. On account of the elevated operating

temperatures, the filaments are made of tungsten, with best possible

avoidance of contact between filament and insulation parts. Insulating

PBN ceramic parts are fully shielded by tantalum plates to prevent

outgassing during operation.

The HTEZ-W works completely without any additional

ceramic insulation.

HTEZ cells are highly efficient, enable a very reproducible temperature

measurement and allow precise adjustment as the thermocouple measuring

point is close to the crucible.

Well-designed tungsten filaments have proved to be very stable, thus

safeguarding a long lifetime even when working on the upper limit of the

cells.

The HTEZ design allows mounting ceramic crucibles (e.g. PBN, BeO, etc.) directly into the cell without an outer metal crucible. In this way a higher temperature of the evaporation material in the crucible can be achieved.

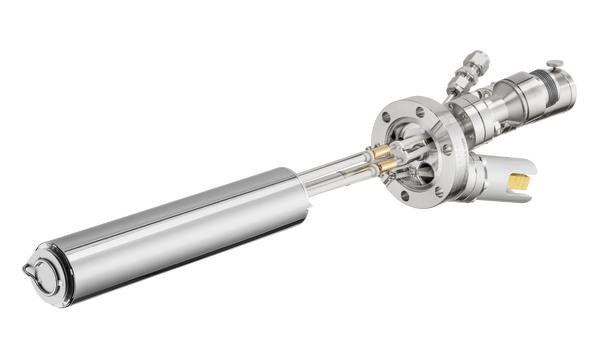

The small HTEZ model with 1.5 cm³ crucible is by default mounted in a cooling shroud (with shutter option) on a DN40CF (O.D.2.75") flange, having a maximum outer in-vacuum diameter of 36 mm.

Separate cooling shrouds are recommended for larger HTEZ cells to avoid overheating of stainless steel parts within the UHV chamber during operation. Some of the larger cells can be delivered with an integral shutter on the cell flange.

Application

The HTEZ is designed for evaporation or sublimation of low vapor pressure elements and compounds at temperatures up to 1900°C, e.g. for materials like Fe, Cr, Ni, Co, Au, Ge etc. Typical applications are surface science analysis or thin film deposition of magnetic or oxide layers.

The maximum operating temperature of the HTEZ may be limited by the crucible choice, e.g. to 1600°C with PBN. Furthermore, possible reactions of evaporants with the crucible material should be taken into account, which may also reduce the maximum advisable temperature.

Please refer to the Selection Guide for material data and decision-making advice.

Technical Data

| Filament type | self-supporting tungsten filament |

| Thermocouple | W5%Re/W26%Re (type C) |

| Operating temperature | max. 1900°C, depending on crucible material and filament design |

| Outgassing temperature | max. 1900°C, depending on crucible material |

| Bakeout temperature | 250°C |

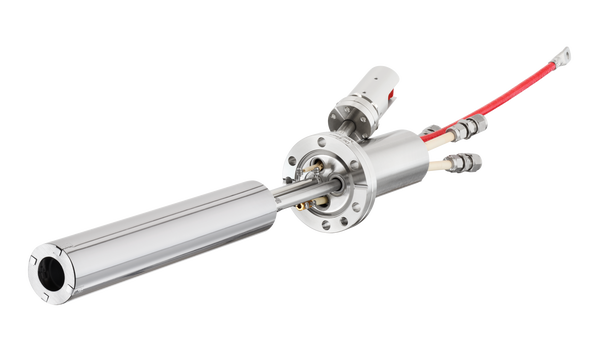

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 1.5, 10, or 35 cm³; Al2O3 , BeO, Ta, W crucibles (other materials on request) |

| Options | integrated water cooling ( K ), integrated rotary shutter ( S ) |

Crucibles

Standard crucible sizes are 1.5, 10 and 35 cm³ (other shapes and

dimensions available upon request).

Different crucible materials such as Al2O3 ,

BeO, Ta, W, pyrolytic graphite (PG) and pyrolytic boron nitride (PBN)

can be applied. For detailed information on crucibles see

Crucibles .

The second number of the product code is the nominal crucible capacity [in cm³]; the third number indicates the lip diameter of the crucible. Please specify crucible material upon ordering, or inquire for our recommendation.

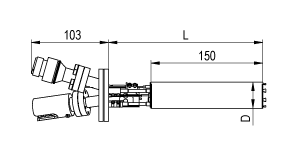

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||

| HTEZ | 40 - | 1 - | 20 - | S - | B - | LxxxD34 | 245 / 13 | PS 40-19 | CRU 1-20 | ||

| HTEZ | 40 - | 1 - | 20 - | K | S - | B - | LxxxD36 | 245 / 13 | PS 40-19 | CRU 1-20 | |

| HTEZ | 40 - | 10 - | 32 - | S - | B - | LxxxD36 | 625 / 13 | PS 80-19 | CRU 10-32 | ||

| HTEZ | 63 - | 10 - | 32 - | K | S - | B - | LxxxD57 | 625 / 13 | PS 80-19 | CRU 10-32 | |

| HTEZ | 63 - | 35 - | 37 - | S - | A - | LxxxD45 | 1075 / 16 | PS 80-19 | CRU 35-37 | ||

| HTEZ | 63 - | 35 - | 54 - | S - | A - | LxxxD56 | 1075 / 16 | PS 80-19 | CRU 35-54 | ||

| HTEZ | 100 - | 82 - | 71 - | K | P - | LxxxD95 | 1360 / 17 | PS 100-24 | CRU 82-71 |

* rotary shutter possible on same flange ** no standard, inquire for your particular solution *** specify UHV length L with order

Product code: e.g. HTEZ 40-10-32-A-L287D36 is a high temperature effusion cell on DN40 CF-flange for a 10 cm³ crucible (lip Ø 32mm), Al2O3 crucible, in-vacuum length 287mm and diameter 36mm.