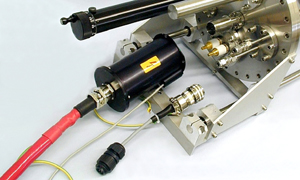

- GENIUS evaporator control unit

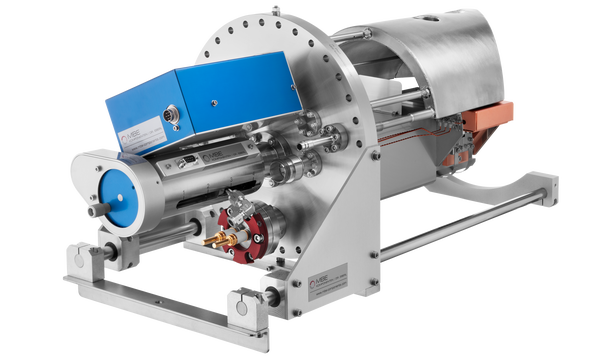

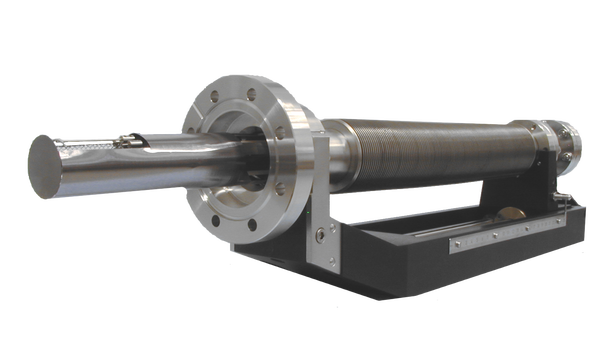

- CARRERA high-voltage power supply (3 kW, 5 kW or 10 kW)

- FPS filament power supply

Introduction

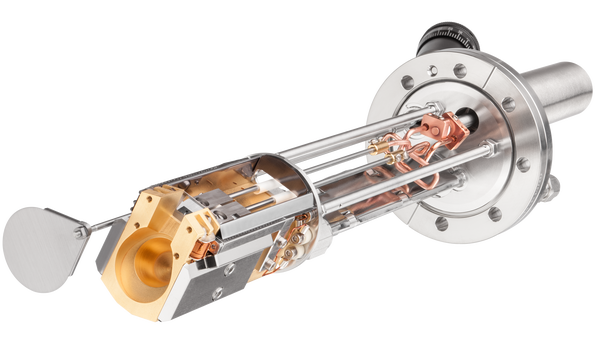

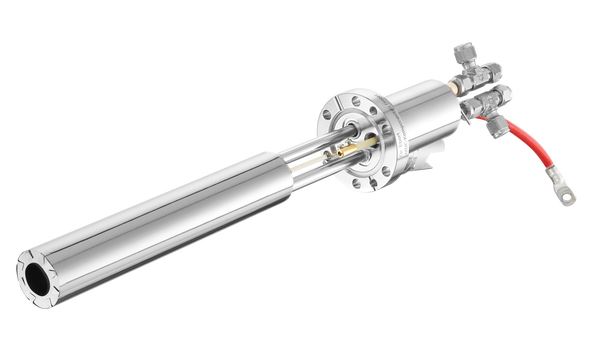

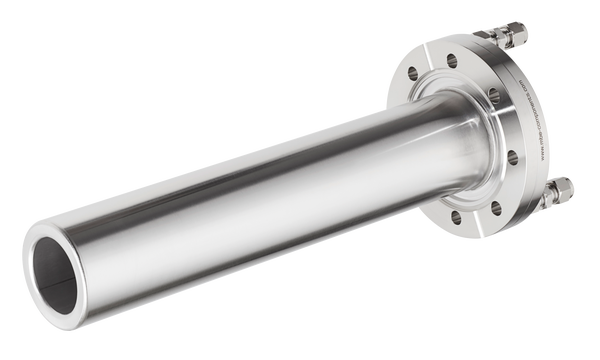

The operation of any electron beam evaporator requires a well-matching set of power supplies and a control unit, in order to generate and guide the electron beam. The high-voltage power supply must deliver the electron-emission current at several kV to the cathode of the emitter assembly.

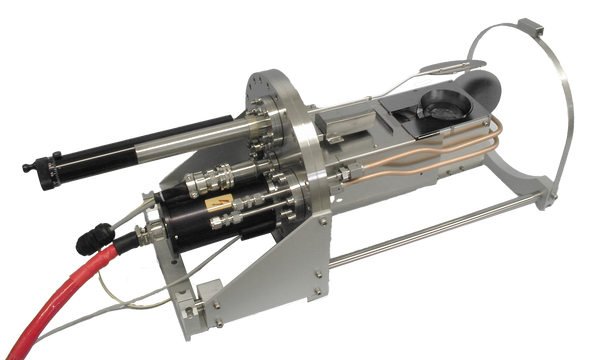

A high-current filament power supply FPS, floating at the high-voltage potential, is further needed to heat the electron-emitting filament. The control unit is responsible for all security issues, the beam positioning and power setting, thus basically providing the user-interface for the whole e-beam evaporation system. For all our e-beam evaporators, EBV, EBVV and EBVM, we offer the GENIUS evaporation controller together with a CARRERA high-voltage power supply and the matching filament power supply FPS.

This combination offers several benefits:

GENIUS CARRERA Fully menu-driven programming and control, high

flexibility, single and multi-hearth control Primary switched mode power

supply (no heavy transformers) Hand-held remote control featuring LCD

display and joystick control High voltage range: 4 kV to 10

kVcontinuously variable Beam sweep and position control Compatible with

most types of e-beam evaporators and

thickness / rate controllers Compact design (19" rack mountable) RS 232

interface for remote operation and control Analogue input for emission

regulation by external rate controller Arc detection and suppression

within 1µs Option: automatic pocket indexing card for multi pocket

evaporators with motorized pocket shift (e.g. EBVM-series) Full arc

recovery within 3 ms Power mains: 85 - 264 VAC, 50/60Hz Power mains:

(specify when ordering)3 x 400 VAC, 50/60Hz or 3 x 208 VAC, 50/60Hz (US)

CE certified CE certified

Rate Feedback Control

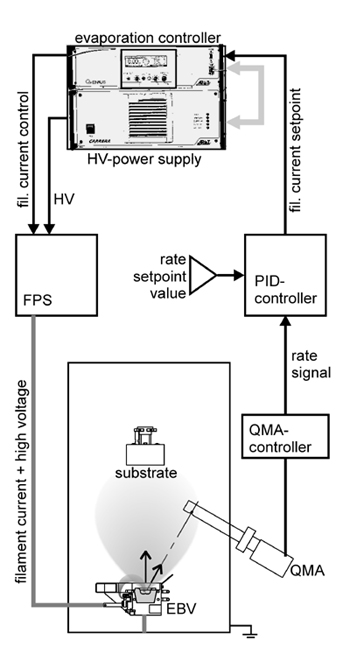

Compared to a simple radiation-heated effusion cell, the precise rate control of the molecular beam flux from an e-beam evaporator needs a little more effort.

Due to thermal fluctuations in the melt and the high power density at the e-beam focus, random short-term flux variations are usually observed. In addition, a change in the heat transfer properties from the evaporant to the water cooled crucible walls can cause flux changes at a constant e?beam power.To achieve a constant evaporation rate from an electron beam evaporator, a flux- or rate-feedback control often is desirable in MBE applications.This can be accomplished by different flux-measurement techniques, e.g. with a cross-beam mass spectrometer detecting the actual evaporant atoms from the source, with a quartz crystal balance or with optical detection methods.

The rate signal is given to a PID-feedback controller, which regulates the emission current of the electron beam to the desired setpoint value, thus achieving a constant beam-flux from the EBV. The GENIUS evaporation controller has for this purpose a built-in analogue input for remote control of the emission current. Hence, it can be easily integrated in such a feedback loop.An example of a feedback set-up with a crossbeam quadrupole mass spectrometer is shown in Fig. 109.If you wish to set up a feedback regulation with the EBV, please contact us for advice.

We can provide you with a complete feedback regulation system adapted and optimised to your growth environment, including flux measurement equipment and PID feedback controller. Please ask for a customised quotation for your application.

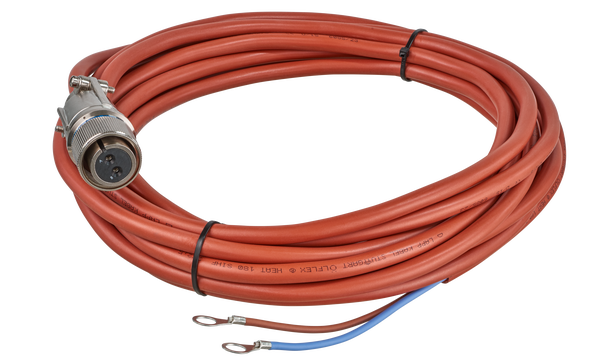

Cables between power supplies and the EBV 200-100 are always an integral part of the power-supply-ensemble. The standard length of the high-voltage cable between the FPS and the evaporator on the vacuum system is 3 m. It can be extended to maximum admissible length of 5 m for this connection.The CE-conform high-voltage connector mates with the HV-feedthroughs on the EBV (M/V) flange (see Fig. 108).In contrast, the x-y beam deflection cable from the GENIUS controller to the EBV can be tailored to custom length (6m is standard).

The high voltage power supply CARRERA is available with three different output power ranges: 3kW, 5kW and 10kW. For most molecular beam applications 3kW or 5kW are largely sufficient. However, the 10 kW version may be necessary for some materials. The GENIUS control unit and the FPS are always the same. We recommend the 5kW CARRERA as the most flexible yet affordable solution assuring to be prepared for possible higher power needs in future applications.

Dimensions

| Device | Height | Width | Depth |

| GENIUS control unit | 132,5mm (3U) | 483mm (19" rack insert) | 200 (+100*) |

| CARRERA HV-supply | 177,5mm (4U) | 483mm (19" rack insert) | 550 (+100*) |

| FPS filament power supply | 235mm | 235mm | 330mm |