- Up to 1021 /ccm Boron doping in Si-MBE

- Evaporation of elemental Boron or Si-B alloy in vertical e-beam evaporator

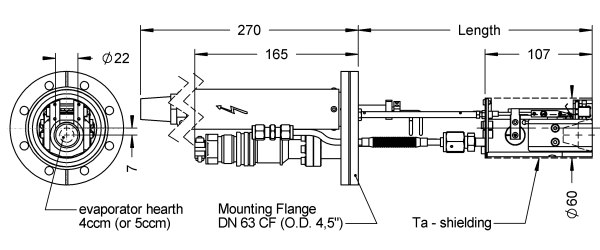

- Small dimensions; can be used in DN63CF (O.D. 4.5“) effusion cell ports; hearth volume 5 cm³

- Long filament lifetime and easy maintenance

- 270° beam deflection

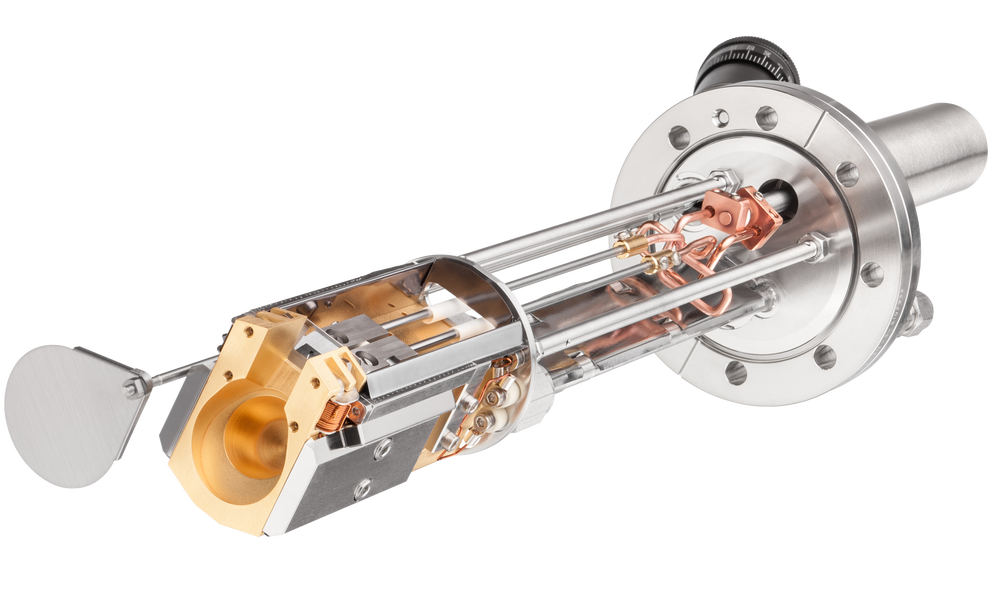

- High frequency x-y-beam deflection system

- Silicon shielding parts for use in SiGe-MBE Datasheet

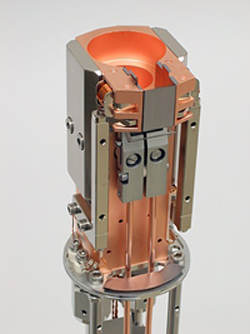

Introduction

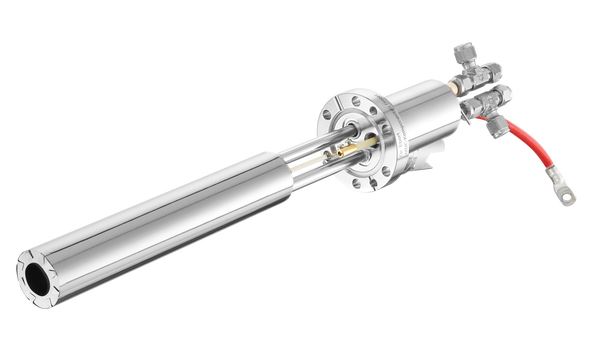

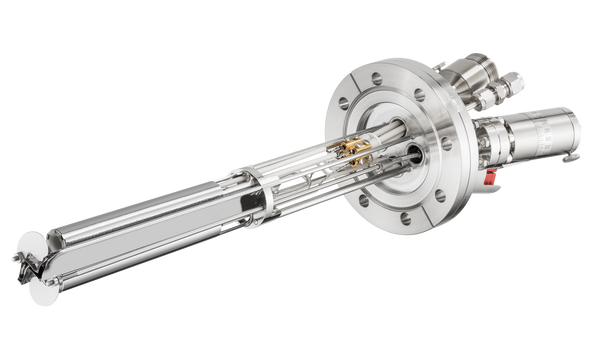

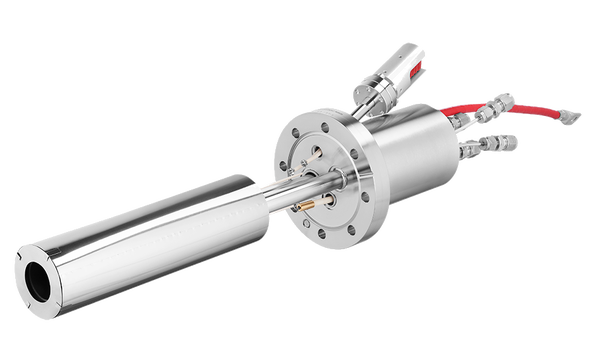

The Vertical Electron Beam Evaporator EBVV-B 63-5 allows to introduce real e-beam evaporation into your MBE system that has originally been designed for effusion cells only.

The unique and extremely compact design permits to install the EBVV-B 63 instead of an ordinary effusion cell on any MBE system having CF63 ports with an I.D. ≥ 60 mm. Even tilted ports can be used. Despite its small footprint, the new EBVV-B 63 includes a complete electromagnetic x- and y-dynamic beam deflection system and can deliver beam powers up to 3 kW.

The evaporator hearth volume is 5 cm³.

The 270° beam deflection design of the electron emitter eliminates nearly all ion bombardment on the filament due to a sharply bent electron beam path near the beam exit aperture. Thus, the filament is well shielded from evaporant or charged particles ejected from the crucible.

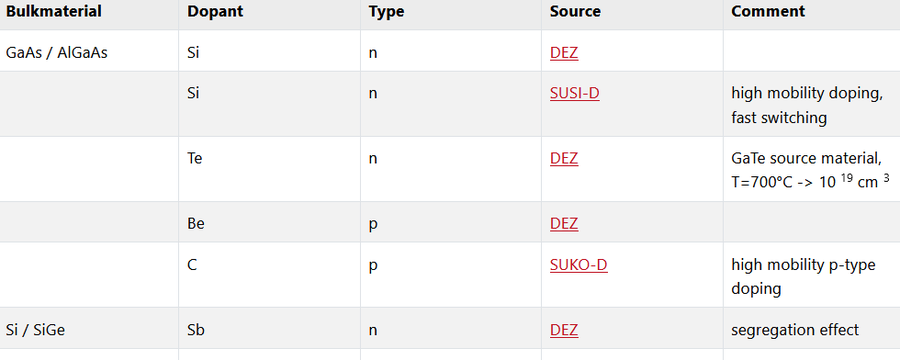

Application

The EBVV-B 63-5 allows high purity evaporation of elemental boron or Si-B alloy. Consequently, it allows Si and SiGe MBE growth of highest Boron doped epi-layers with Boron concentrations up to 1021/ccm.

This concept is applied in Si/SiGe HBTs or Si based Esaki-Diodes with record peak-to valley ratio and current density. The SIMS profile below shows a 275 nm Si layer with high Boron doping.

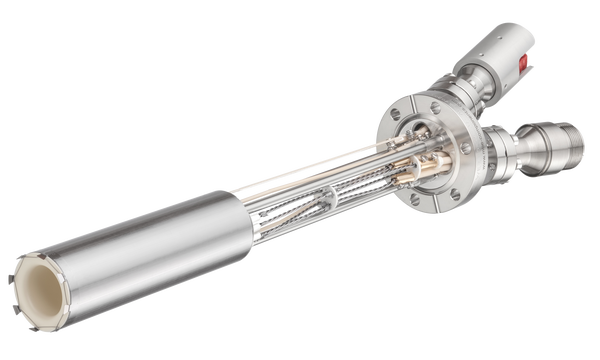

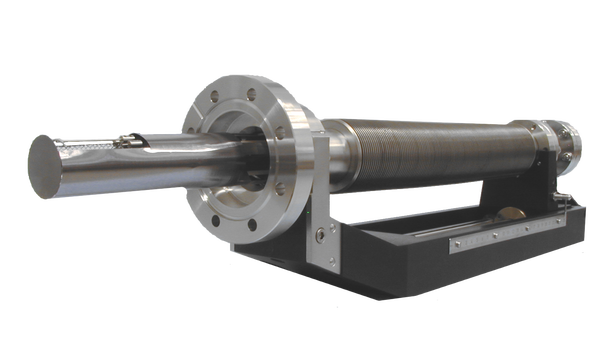

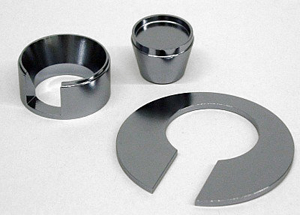

Silicon shielding parts

The EBVV-B is equipped with a specially adapted set of shielding parts manufactured from high-purity single crystalline Si. A Si plate and a ring cover all parts of the metallic body that are potentially subject to electron or ion bombardment and that face the substrate.

Only this Si-shielding allows the growth of highest purity Boron doped Si and SiGe films.

We also supply high purity Si-B source material in superior quality. It is machined and pre-conditioned from wafer-grade Si-single crystals and high purity Boron, fitting the evaporator hearth.

Technical Data

| Mounting flange | DN63 CF (O.D.4,5“) or DN100 CF (O.D.6“) |

| Dimensions in UHV | Length: 234 – 450 mm (user specific); ØD: 60 mm |

| Crucible capacity | 5 cm³ |

| Hearth dimensions | Ø 23 mm (12° taper) x 15 mm |

| Filament type | short-legged coil of W wire, electron emitting filament |

| Bakeout temperature | 200° (all air side connectors removed) |

| Operating pressure | 1 × 10-11 mbar ….1 × 10-5 mbar |

| Accelaration voltage | 4 - 6 kV |

| Beam power | max. 3 kW |

| Filament current | max. 25 A at 10V (AC) |

| Spot size | 5 mm diameter, approx. |

| Primary beam deflection | C270° by permanent magnet system |

| Dynamic beam deflection | coils wound from KAPTONTM isolated wire; defl. frequency: max. 150 Hz; x-deflection current: ± 1,5 A max.; y-deflection current: ± 2 A max. |

| Water cooling | Min. water flow rate 5 l/min at 4 bar |

| Options | Tilted hearth (T); integrated rotary shutter (S) |

Dimensions