- 1020 /cm3 n-type doping in Si/SiGe MBE

- P-doping through GaP decomposition

- High P incorporation rate

- Minimum memory effects

- Easy to install and to operate

- Sharp doping profiles

- Precise and fast flux control

Introduction

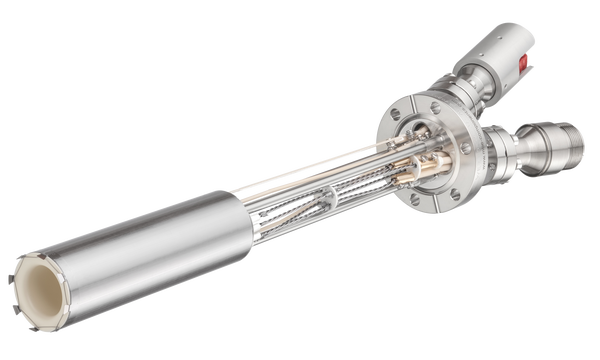

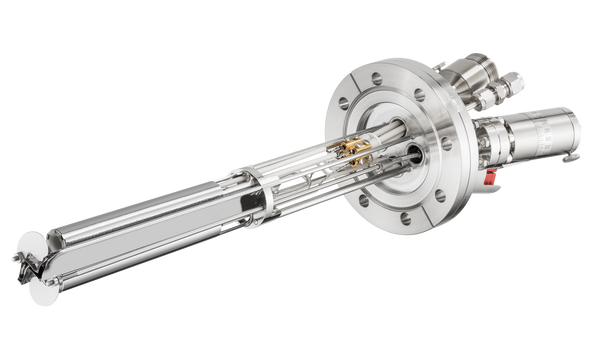

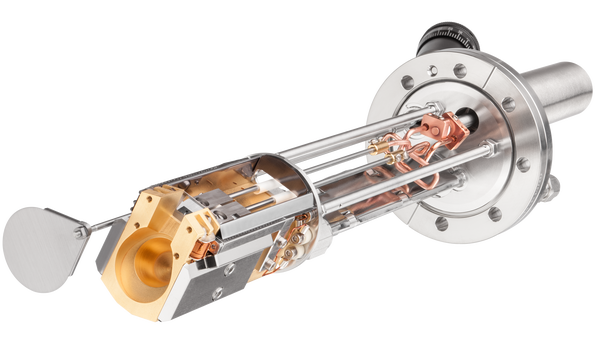

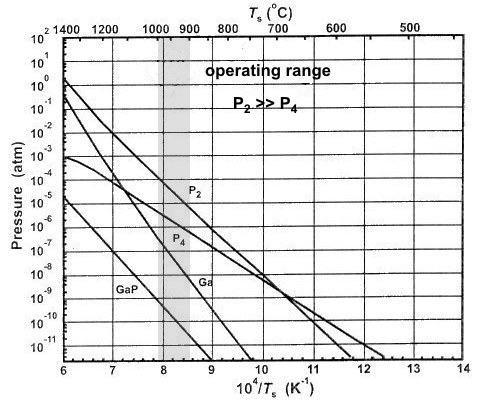

The Phosphorus Doping Source DECO-D is an ultra pure source for P 2 , based on the decomposition of GaP. At typical operation temperatures of about 600°C - 700°C GaP is essentially decomposed to Ga and P2 . Additional cracking is not necessary and the accumulation of P4 (White Phosphorus) is reduced to a minimum.

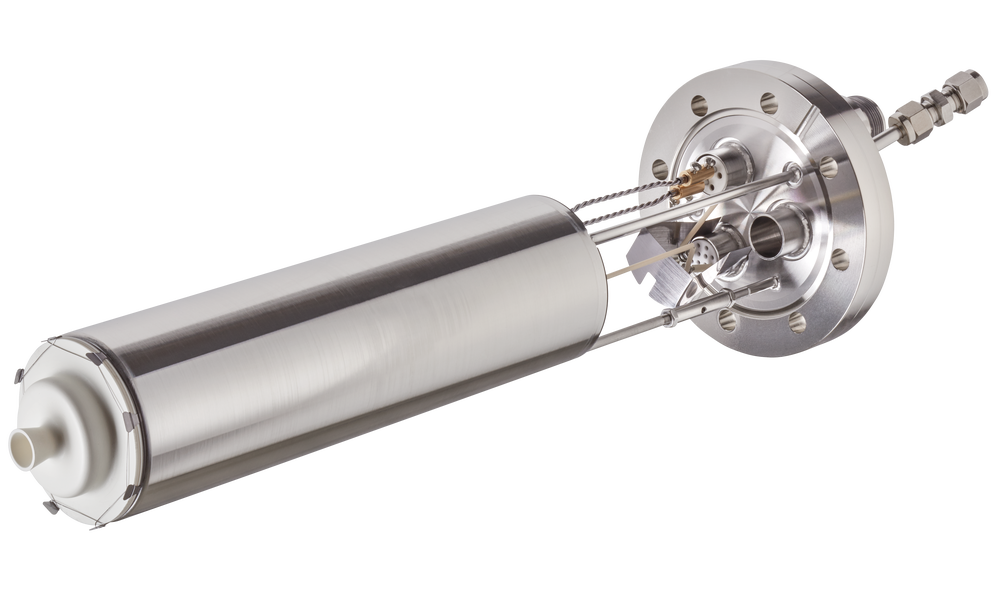

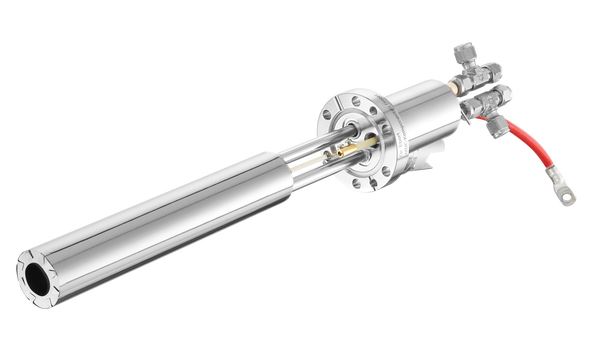

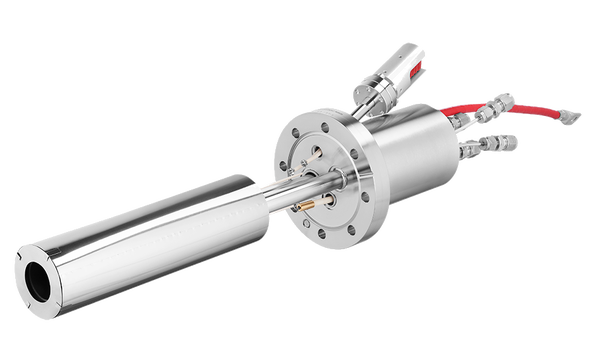

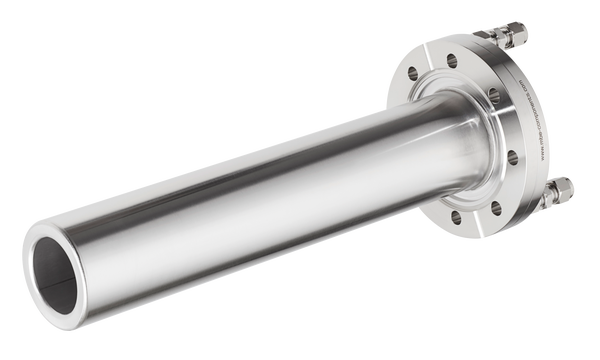

The simple construction of the DECO-D, based on our WEZ and PEZ cells, and the specially designed Ga-Trapping-Cap System have the advantages of easy mounting, full compatibility to all MBE systems, high reliability and low cost. The operation of the DECO-D is comparable to usual effusion cells and does not require complicated mechanical valves and controllers. MBE-Komponenten GmbH has developed special sources based on the Ga-Trapping-Cap System. We build the DECO-D optimized for special doping applications, e.g. as phosphorus doping cell for Si MBE with a reduced cell shutdown time.

The heater of the DECO-D is designed very similarly to the WEZ-heater which consists of a Ta wire filament supported by PBN rings. Crucible material is PBN. With this design minimum outgassing at operation temperature is achieved, in combination with excellent reliability, long-term stability and extended lifetime.

Excellent operation temperature stability of ±0.1°K is achieved by an improved design of the thermocouple assembly. This assembly touches the crucible near the base. The direct touch technique and the use of double pairs of TC-alloy wires ensure a reproducible and stable measurement of the real crucible temperature.

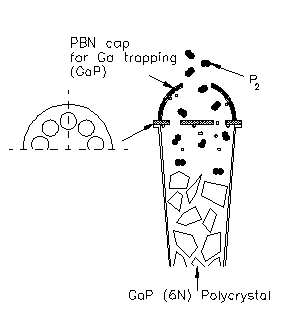

Ga-Trapping Cap Unit

The DECO source features a unique Ga-Trapping Cap Unit system that provides a very pure P2 beam by decomposition of GaP. The idea underlying that unit is the sublimation of phosphorus from GaP at rather moderate temperatures at which gallium has only a negligible vapor pressure. By special baffle plates parasitic Ga atoms are efficiently separated from the P2 beam, thus producing a very pure P2 flux.

The Ga-Trapping Cap Unit is a simple but effective design consisting of only a small number of well-designed parts which are mounted onto the PBN crucible without additional tools or holders. For source maintenance and crucible refilling the unit is likewise easily removable.

Upon special request, a complete Ga-Trapping-Cap Unit is available as a

product of its own, for retrofitting standard effusion cells.

Inquire for further information on compatibility.

operating temperatures 900-1200°C for growth applications

precise adjustment of P2 incorporation into GaAsP. GalnAsP, etc., compound layers

P2:P4 ratio about 150:1

very low parasitic Ga flux (P:Ga > 105)

(P:Ga > 103 without Ga-Trapping Cap Unit)high efficiency : about 20 g P in GaP for 100µm film thickness

marginal white phosphorus accumulation in MBE system

no additional safety facilities needed in contrast to PH3 , AsH3 or valved elemental phosporus crackers

no bakeout necessary before opening the system

compatible with standard III/V solid source MBE

Application

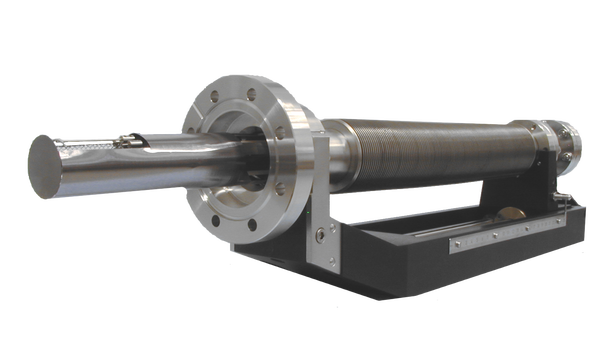

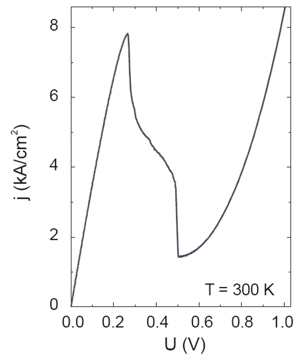

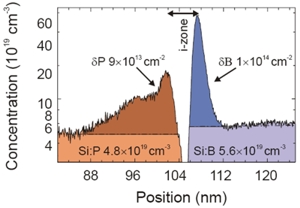

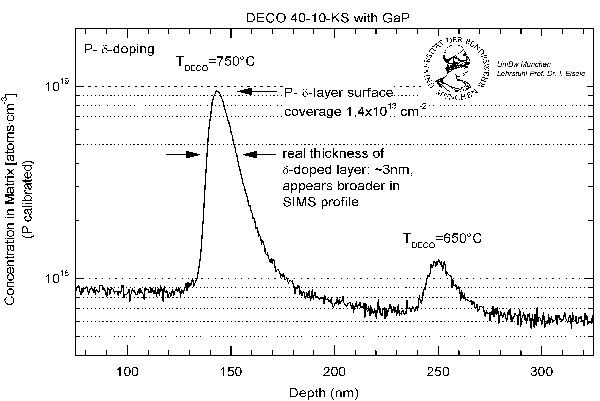

Typical applications of our DECO-D phosporus doping source are high level and sharp delta-doping with Phosphorus in Si/SiGe MBE. Small crucible charges, large double layer shutters, integrated water cooling and reduced shielding allow a fast shutdown of the cell after the doping. High 10 20 /cm 3 doping and sharp delta-doping have been reported in literature applying the DECO-D from MBE-Komponenten GmbH. Due to its small dimensions and easy operation the DECO-D is ideally suited for all types of MBE systems.

Single crystal GaP material with a purity >6N is recommended as source material.

The DECO-D has been successfully operated in many MBE laboratories worldwide. The following three figures demonstrate the unique performance of devices fabricated by means of the DECO-D.

The figure below shows a sharp P-doping profile in a Si layer with two P-delta-layers. The experiment was performed at the Universät der Bundeswehr in Munich, in the group of Prof. Eisele.

References

There are several publications based on P-doping in Si MBE with DECO-D sources.

| Filament type | Ta wire heating filament, optimized for doping application |

| Thermocouple | W5%Re/W26%Re (type C); type K on request |

| Operating temperature | 600-700°C for doping applications |

| Outgassing temperature | 1500°C |

| Bakeout temperature | 250°C |

| Cooling | integrated water cooling or separate cooling shroud |

| Crucibles | 10-35 cm³ PBN crucibles |

| Options | integrated water cooling shroud ( K ), integrated shutter ( S ) |

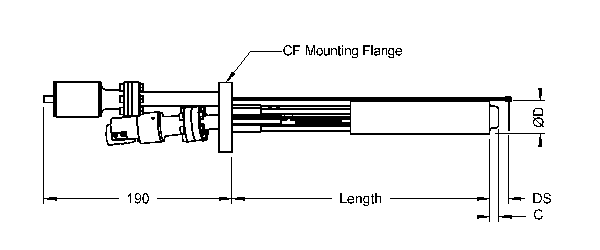

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Lip diameter | Cooling | Shutter* | Thermocouple | Crucible material** | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | Crucible product code | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [cm³] | [mm] | Type | [mm] / [mm] | [W] / [A] | Product code | Product code | ||||||

| DECO-D | 40 - | 10 - | 22 - | S - | C - | P - | LxxxD34 | 120 / 6 | PS 30-10 | CRU 10-22 | ||

| DECO-D | 40 - | 10 - | 22 - | K | S - | C - | P - | LxxxD36 | 120 / 6 | PS 30-10 | CRU 10-22 | |

| DECO-D | 40 - | 35 - | 34 - | S - | C - | P - | LxxxD35 | 180 / 7 | PS 30-10 | CRU 35-34 | ||

| DECO-D | 40 - | 60 - | 37 - | C - | P - | LxxxD38 | 240 / 8 | PS 30-10 | CRU 60-37 | |||

| DECO-D | 63 - | 35 - | 34 - | K | S - | C - | P - | LxxxD60 | 180 / 7 | PS 30-10 | CRU 35-34 |

* rotary shutter possible on same flange ** PBN standard *** specify UHV length L with order

Product code: e.g. DECO-D 40-10-22-KS-C-L277D36 is a phosphorus doping source on DN40 CF-flange for a 10cm³ crucible (lip Ø 22), integrated water cooling shroud, shutter, type C thermocouple, in-vacuum length 277mm and diameter.