SUKO-D

Carbon Doping Source

SUKO 40 Carbon Sublimation Source on DN40CF (O.D. 2.75") flange

-

High-mobility GaAs p-type doping

-

Fast and precise flux control

-

Ultra-high purity pyrolytic graphite (PG) filament

-

Water-cooled electrical contacts

-

Inner filament shielding with pure pyrolytic graphite parts

-

No ceramic or metal parts in the hot zone

|

The Carbon Doping Source SUKO-D is a highly optimized doping source for carbon p-type doping in III-V MBE. The SUKO-D provides a very clean and constant flux at low deposition rates of up to 2 Å/min. For growth applications a maximum total layer thickness of 5 µm C with one filament is reported, equivalent to layers of up to 1mm of highly carbon-doped GaAs. |

Main parts of the SUKO-D assembly |

|

At typical operation conditions the SUKO-D filament is glowing at a temperature of about 2200°C. Especially for heat sensitive substrate materials it should be taken into account that a lot of radiation is impinging on the surface of the substrate during exposure. The SUKO-D uses water-cooled power feedthroughs and contacts to provide ultra-pure operation conditions. An additional surrounding cooling should be provided to avoid overheating of stainless steel parts within the UHV chamber. |

|

Operation and Results

|

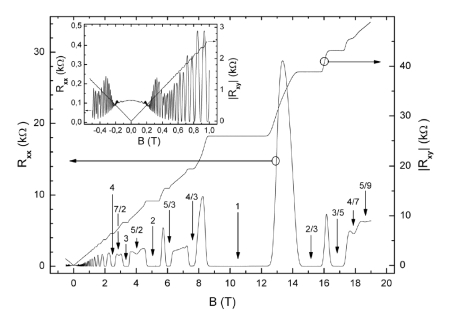

The figure shows an excerpt of the results of C. Gerl with the redesigned SUKO-D. |

| Longitudinal and Hall resistance at a bath temperature <30mK. (C. Gerl et al. "Carbon doped symmetric GaAs/AlGaAs quantum wells with hole mobilities beyond 106cm2/Vs", Appl. Phys. Lett. 2005). |

During operation the SUKO-D filament becomes thinner and thereby the flux rate very slowly increases. The current should therefore be recalibrated and reduced from time to time in order to keep the flux rate constant.

The lifetime of a graphite filament strongly depends on the proper control of the flux rate. This is of special importance when operating at higher currents where a runaway increase of the flux rate can result in premature burning out of the filament.

Application

The SUKO-D is successfully used in III-V MBE for p-type doping by customers all over the world. A list of publications based on samples grown by using SUKO-D and SUKO is shown below.

In general, the electron mobility turns out to be comparable to those achieved by Be doping. Optical, REM and x-ray studies all confirmed the excellent morphology of the layers. Due to the very effective water cooling of the metal contacts and the shielding of the hot source material by pyrolytic, non-porosity graphite the vacuum conditions during operation are remarkable.

In contrast to carbon gas sources no interaction with MBE equipment or memory effect is observed while operating the SUKO-D.

Carbon doping in III-V MBE with the SUKO-D

Achievable doping levels with the SUKO:

- The maximum bulk p-doping level of GaAs (measured at 300K) is 6.5x10">19 cm-3, with a mobility of 29 cm²/Vs.

- The maximum bulk doping level of GaAlAs (35% Al, thickness 1500 Å) (measured at 300K) is 7.5x1019 cm-3, with a mobility of 28 cm²/Vs.

- The maximum delta doping level in GaAs is 2x1013 cm-2.

- Minority carrier lifetime in p-doped GaAs (1.7x1019 cm-3) is 140ps.

Excellent ohmic contacts have been prepared on highly carbon doped GaAs by deposing CrAu layers without any subsequent annealing. This is particularly interesting for a lower contact resistance in laser devices.

The SUKO-D was carefully redesigned in collaboration with Prof. W. Wegscheider in the University Regensburg (Germany). In his high mobility MBE system he reproducibly achieved record hole mobilities of 1.2x106 cm2/Vs in GaAs/AlGaAs quantum wells at a carrier density of 2.3x1011cm-2 (see References below).

The new SUKO-D uses a directly heated and specially pre-conditioned high purity pyrolytic graphite filament that puts minimized heat load onto the MBE system and provides a long filament lifetime. It is particularly well suited for extremely high bulk doping levels, sharp delta doping layers, modulation doping and low resistance p-type contact formation. Various design features contribute to a very fast temperature ramping and flux switching without any memory effect in the system.

The applications range from MBE growth of III/V heterostructures for basic research to electronic and optoelectronic device fabrication, as for example high power laser diode growth.

References

Several publications based on samples grown with SUKO-D sources are listed in section References / List of Publications.

Technical data |

|

| Filament type | high purity graphite filament |

| Filament shielding | filament completely shielded with PG parts |

| Thermocouple | W5%Re/W26%Re (type C) |

| Operating temperature | max. filament temperature 2300°C |

| Bakeout temperature | 250°C |

| Electrical contacts | water-cooled (4x Swagelok fitting connection O.D. 6mm); water flow min. 30l/h |

| Cooling | separate water (or LN2) cooling shroud |

| Options | shutter available in combination with additional cooling shroud |

Dimensions

|

Schematic drawing of the Carbon Sublimation Source SUKO-D (drawing shows SUKO-D 40) |

Specific data

For general information on CF mounting flanges see Flange and Gasket dimensions.

|

|

|

|

|

|

|---|---|---|---|---|---|

| [mm] / [mm] | [W] / [A] | Product code | |||

| SUKO-D | 40 - | LxxxD36 | 600 / 75 | PS 20-76 |

| *** | specify UHV length L with order |

Product code:

e.g. SUKO-D 40-L300D36

is a carbon doping source on DN40 CF-flange with in-vacuum length 300mm and diameter 36mm.

Related products

The following list provides suggestions for related products. For additional product suggestions or more detailed information, please contact us.

Components

|

|

|

| Carbon Sublimation Source SUKO |

Atomic Carbon Sublimation Source SUKO-A |

Vertical Electron Beam Evaporator EBVV |

Accessories

|

|

|

| Cooling Shrouds CS | Quartz Crystal Monitor QCM |

Systems

|

|

|

| OCTOPLUS 300 | OCTOPLUS 400 | OCTOPLUS 600 |