- Fully UHV compatible

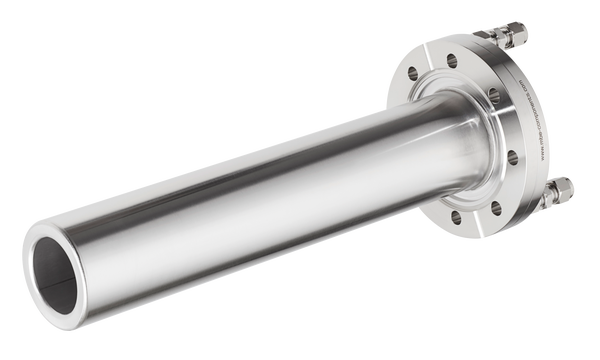

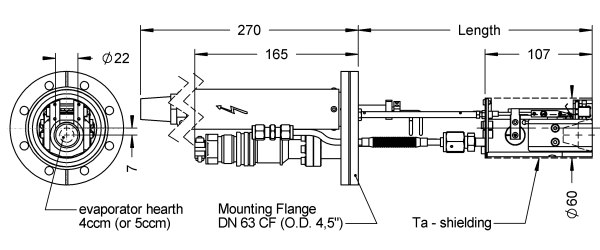

- Small dimensions fit onto DN63CF (O.D. 4.5’’) ports

- Hearth volumes 4 cm3 or 5 cm3

- High purity evaporation of metals and dielectrica

- Long filament lifetime and easy maintenance

- 270° beam deflection

- High frequency x-y-beam deflection system

- Silicon shielding parts for use in SiGe-MBE Datasheet

Introduction

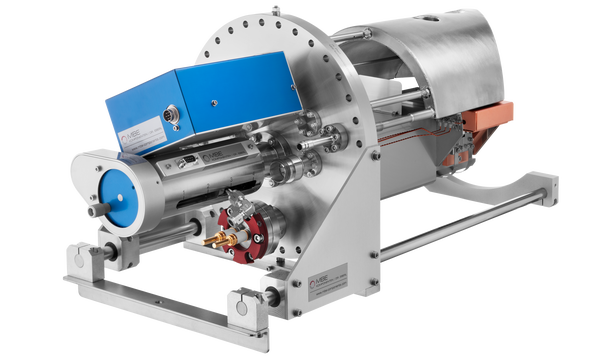

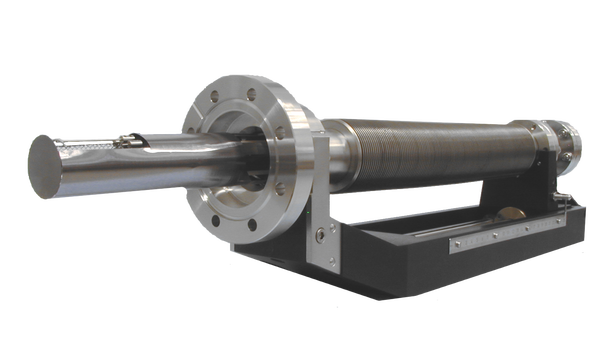

The Vertical Electron Beam Evaporators EBVV allow the user to introduce

real e-beam evaporation into many growth systems originally designed for

radiation heated effusion cells only. Despite its small footprint, the

EBVV features a complete electromagnetic x- and y-dynamic beam

deflection system and is capable of delivering beam powers up to 3kW @

6kV.

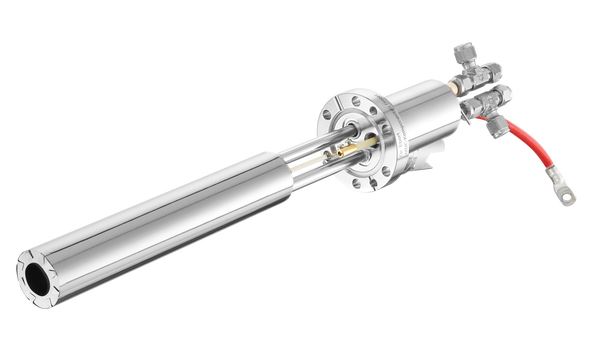

Its unique and extremely compact design makes it possible to install the

EBVV instead of an ordinary effusion cell onto any MBE system having

a (near) vertical DN63CF port with I.D. >= 60mm.

Inclined ports can be used without any difficulty for sublimating

crucible charges. For materials that become liquid during operation EBVV

evaporators are available with a tilted hearth geometry on request.

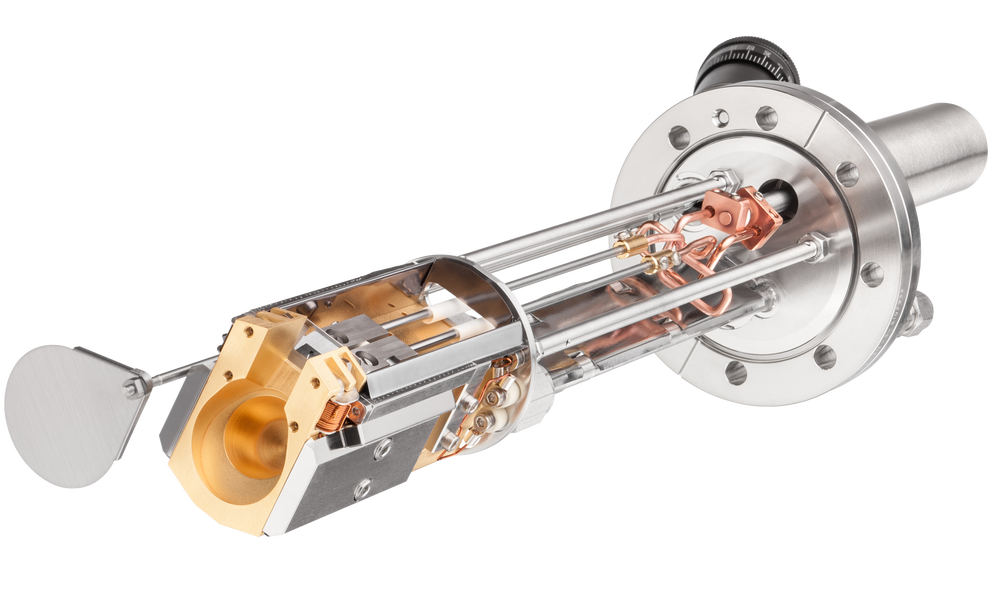

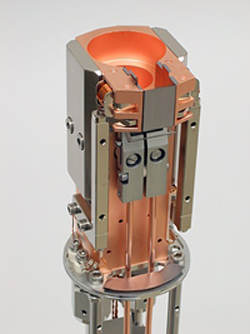

Especially for hot parts only UHV-grade materials are used without any compromise: molybdenum emitter block, tungsten filament and Al 2O3 insulting ceramics. The main body is manufactured from OFHC (Oxygen-Free High Conductivity) copper and closely surrounded by a complete turn of an Ω-shaped water channel for most effective cooling.

Two different hearth volumes are available: the 4 cm3 (O.D. 22mm, taper 15°) geometry is compatible with standard crucible liners, while the 5 cm3 (O.D. 23mm, taper 12°) model is recommended for Si epitaxy (in combination with specially adapted silicon shielding parts).

The 270° beam deflection design of the electron emitter eliminates nearly all ion bombardment on the filament, due to a sharply bent electron beam path near the beam exit aperture. In this way, the filament is well shielded from evaporant or charged particles ejected from the crucible. In addition, the sample is shielded from direct sight onto the hot tungsten filament, further reducing the chance of sample contamination by impurities from the hot emitter area.

Application

The small dimensions and the vertical evaporator design open the path to a new range of applications:

In standard MBE systems and the majority of home-made UHV chambers there are often no horizontal ports designated for typical e-beam evaporators. Here the compact design of the EBVV allows the integration of a powerful electron beam evaporator into virtually every UHV growth system.

The EBVV closes the gap between small rod-fed e-guns, usually providing very low fluxes and only suitable for sublimating evaporants, and common horizontally mounted e-beam evaporators, which often are excessively space-consuming and far overrated for most MBE applications. EBVV evaporators may even be a good alternative to radiation heated high temperature sources running into their flux. temperature or purity limits

The EBVV is the ideal evaporator for any low or very low vapor pressure material, including refractory metals or dopants such as boron or carbon. It can also serve the upcoming demands in newly developed material systems like high-k materials (Al2O3 or Pr3O3 ) or other oxides and dielectrics.

For metal deposition the EBVV 63-4 can be used with bare copper hearth,

in particular for all metals that do not melt completely (e.g., Al) or

that are not reacting with the cooled copper wall. Crucible

liners manufactured from graphite or refractory metals are available

for other materials.

Please inquire about a solution for your particular evaporation

material.

For Boron doping applications we offer the specialized e-beam evaporator type EBVV-B.

SiGe MBE is another key application for the EBVV. For Si growth in an MBE system the use of the EBVV 63-5 is recommended because hearth capacity and geometry are optimized for this special application.

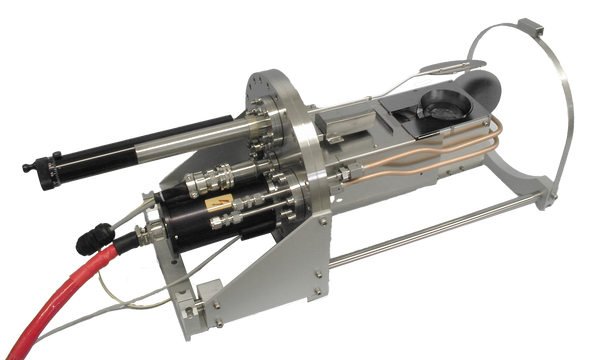

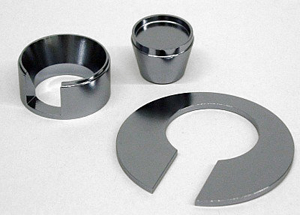

A set of specially adapted shielding parts manufactured from high purity

single-crystalline Si is available for this model. All parts of the

metallic body that are potentially subject to electron or ion

bombardment and that face the substrate are covered by a top Si plate

and ring.

This kind of shielding is a qualification for the growth of highest

purity Si-based films with virtually no metallic contamination. The set

is complemented by a high purity Si charge, source material in superior

quality machined from wafer-grade Si single crystals, that fits the

hearth closely.

Technical Data

| Mounting flange | DN63CF (O.D.4,5“) or DN100CF (O.D.6“) |

| Dimensions in UHV | L=234-400 mm; D=60 mm |

| Hearth dimensions | H=15 mm; Ø=22 mm (15° taper) or Ø=23 mm (12° taper) |

| Bakeout temperature | 200° |

| Spot size | 5 mm diameter, approx. |

| Primary beam deflection | 270° by permanent magnet system |

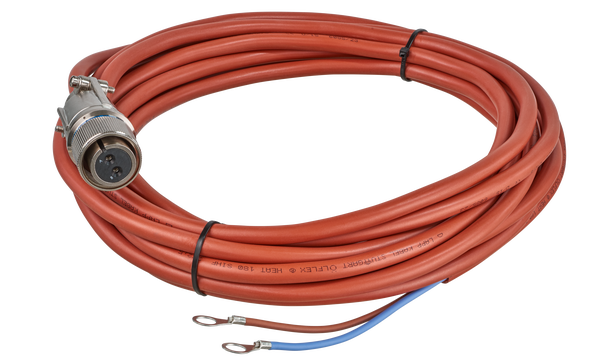

| Water cooling | Min. water flow rate 5 l/min at 4 bar |

| Options | Tilted hearth (T); integrated rotary shutter (S) |

Dimensions

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

| Product | CF flange | Nominal capacity | Shutter* | UHV dimensions*** [mm] | max. electrical [W]/[A] | Power supply product code | |

|---|---|---|---|---|---|---|---|

| [cm³] | [mm] / [mm] | [kW] / [mA] | Product code | ||||

| EBVV | 63- | 4- | S**- | L250-400 / D60 | 3 / 500 | HV | |

| EBVV | 63- | 5- | S**- | L250-400 / D60 | 3 / 500 | HV |

* manual or automated shutter actuation

** same diameter D=60 mm with shutter *** specify UHV

length L with order